the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

MESSAGEix-Materials v1.1.0: representation of material flows and stocks in an integrated assessment model

Florian Maczek

Jihoon Min

Stefan Frank

Fridolin Glatter

Paul Natsuo Kishimoto

Jan Streeck

Nina Eisenmenger

Dominik Wiedenhofer

Volker Krey

Extracting raw materials and processing them into products used in industry constitute a substantial source of CO2 emissions, which are currently lacking process detail in many integrated assessment models (IAMs). To broaden the space of climate change mitigation options to include material-oriented strategies such as the circular-economy and material efficiency measures in IAM scenario analysis, we develop the MESSAGEix-Materials module, representing material flows and stocks within the MESSAGEix-GLOBIOM IAM framework. We provide a fully open-source model that can assess different industry decarbonization options under various climate targets for the most energy- and emissions-intensive industries: aluminum, iron and steel, cement, and petrochemicals. We illustrate the model's operation with a baseline and mitigation 2-degrees (2 °C) scenario setup and validate base year results for 2020 against historical datasets. We also discuss the industry decarbonization pathways and material stocks of the electricity generation technologies resulting from the new model features. The next steps are to extend the model to other sectors, end uses and materials, as well as the combined modeling of various supply- and demand-side measures.

- Article

(2919 KB) - Full-text XML

-

Supplement

(1209 KB) - BibTeX

- EndNote

Extracting raw materials and processing them into products which are used in various end-use sectors such as transportation, residential and commercial buildings, infrastructure, or consumer goods constitute a substantial source of CO2 and greenhouse gas (GHG) emissions. Direct and indirect CO2 emissions from industries constitute 35 % of global GHG emissions (Lamb et al., 2021), and industry constituted 37 % (157 EJ) of the global total final energy use in 2018 (IEA, 2023b). Around 70 % of the industrial CO2 emissions and 50 % of the final energy consumption are due to the production of bulk materials such as aluminum, cement, iron and steel, and petrochemicals (IEA, 2021b). Therefore, options on how to decarbonize these industries by increasing energy and material efficiency, as well as by means of demand-side measures, are increasingly being investigated (Watari et al., 2022; Lopez et al., 2023; Bhaskar et al., 2020). Understanding the potentials of these mitigation measures for reducing GHG emissions then requires model-based assessments of the entire life cycle of materials, from raw-material extraction and industrial processing to the use phase of product stocks, as well as waste management, recycling and end-of-life treatment options.

Integrated assessment models (IAMs) have been used to generate scenarios for assessing energy and industry transformation for limiting climate change. However, recent reviews showed that many IAMs often lack the granularity, resolution and framework to fully depict material flows and stocks (Bataille et al., 2021; Pauliuk et al., 2017; Stern, 2011). Many IAMs either omit physical material supply and demand or model those in a simplified manner by directly relating material flows to economic indicators such as GDP (Pauliuk et al., 2017). Connecting material flows with end-use demand would, however, enable the modeling of such cross-sectoral interactions among material stocks and flows, energy demand, and GHG emissions, as well as various sectoral- and service-provisioning dynamics, which only very few models can currently do in a physically consistent and economy-wide manner (Wiedenhofer et al., 2024a). The tradition of partial-equilibrium IAM modeling covers technology-rich models built on thermodynamic consistency for their respective sector, such as the energy system. Only recently, partial-equilibrium IAMs started to selectively represent material flows and stocks and their energy- and emission-intensive production processes, though the coverage is not the entire life cycle of economy-wide materials. For example, Stegmann et al. (2022) used IMAGE to represent plastics; van Sluisveld et al. (2021) used it to represent iron and steel, cement, chemicals, paper, and pulp; and Deetman et al. (2021, 2020, 2018) used it for specific end-use sectors such as electricity, buildings, vehicles and appliances. Other partial-equilibrium IAMs such as COFFEE, POLES and PROMETHEUS (Rochedo, 2016; Després et al., 2018; Fragkos et al., 2015) include iron and steel, cement, and chemicals.

Herein, we present the MESSAGEix-Materials module, which aims to model the life cycle of energy-intensive materials, starting from raw-material extraction and then moving on to industrial processing, the raw materials' accumulation as material stocks for various end uses, and end-of-life waste flows and recycling, within the MESSAGEix-GLOBIOM integrated assessment modeling framework (Krey et al., 2020). We develop the module based on a conceptual framework that integrates the traditions of energy system modeling with economy-wide material flow analysis. With this development, we provide a fully open-source model and its associated techno-economic data, which can be used to assess different industry decarbonization options under various climate targets for the most energy- and emission-intensive industries: iron and steel, cement, aluminum, and petrochemicals.

MESSAGEix-Materials is operational within the global partial-equilibrium MESSAGEix-GLOBIOM model, which is based on the MESSAGEix modeling framework (Huppmann et al., 2019), incorporating macro-economic feedback using a stylized computable-general-equilibrium (CGE) model, MACRO. The energy system optimization model MESSAGE (Model for Energy Supply Strategy Alternatives and their General Environmental Impact) and the land use model GLOBIOM (GLObal BIOsphere Model) (IIASA-IBF, 2023; Havlík et al., 2014) are the central components of the framework. Based on its scenarios, GLOBIOM is linked to MESSAGE as a parametric land use emulator (Fricko et al., 2017). MESSAGE is a linear-programming (LP), cost minimization, energy-engineering model with global coverage and perfect foresight as a solving method. MESSAGEix-GLOBIOM provides a framework for representing a reference energy system with a full set of available energy conversion technologies, from resource extraction, imports and exports, conversion, transport, and distribution to the provision of energy end-use services such as light, space conditioning, industrial production processes and transportation. More details about the integration of MESSAGEix-Materials into the MESSAGEix modeling framework are explained in Sect. 2.1.

As a system-engineering optimization model, MESSAGEix is primarily used for medium- to long-term energy system planning, energy policy analysis and scenario development (Huppmann et al., 2019; Messner and Strubegger, 1995). The model is designed to formulate and evaluate alternative energy supply strategies consonant with user-defined constraints such as limits on new investment, fuel availability, trade, environmental regulations and policies, and diffusion rates of new technologies (Gidden et al., 2023; Guo et al., 2022; Zhou et al., 2019). Environmental aspects can be analyzed by accounting for and, if necessary, limiting the amounts of pollutants emitted by various technologies at various steps in energy supply. This helps to evaluate the impact of environmental regulations on energy system development. The principal results comprise, among others, estimates of technology-specific multi-sector response strategies for specific climate stabilization targets. By doing so, the model identifies the least-cost portfolio of mitigation technologies. The choice of individual mitigation options across greenhouse gases and sectors is driven by the relative economics of the abatement measures, assuming full temporal and spatial flexibility (i.e., emission reduction measures are assumed to occur when and where they are cheapest to implement).

However, so far, MESSAGEix-GLOBIOM only contains a simplified representation of the industry sector by distinguishing three industrial energy demand categories: thermal, specific and feedstock. Thermal demand, i.e., heat at different temperature levels, can be supplied by a variety of different energy carriers, while specific demand requires electricity (or a decentralized technology to convert other energy carriers into electricity). So far, industrial production processes are not explicitly modeled for those energy demand types. Only the amount of cement production is linked to industrial thermal demand, and the associated CO2 emissions from the calcination process are accounted for explicitly (Krey et al., 2020). The current representation of industrial energy demand is solely derived from GDP, which is not biophysically consistent as there is no link between physical resource extraction, material flows through sectors, accumulated material product stocks and the related energy use.

The MESSAGEix-Materials module presented herein advances this simplified industry sector representation and develops a consistent representation of material extraction, industrial production and processing technologies together with the relevant techno-economic data for the chosen industries. This enables an explicit representation of the primary and secondary material flows occurring in industrial processes and the resulting GHG emissions, opening the way for modeling material-oriented climate change mitigation strategies. For the industries mentioned above, a set of low-carbon technologies, in addition to the conventional technology options, are represented, including recycling for metals. Because capital formation is a major driver of material demand and GHG emissions (Hertwich, 2021), we extend the MESSAGEix model formulation (Huppmann et al., 2019) to also explicitly model material flows and stocks from the existing technologies in the model. We demonstrate the functionality of the new model formulation for the case of electricity generation technologies in terms of it allowing for the endogenization of material demand and end-of-life materials through building up and transforming the infrastructure of these technologies. This formulation can also be used for other technologies in the model, such as machinery in industry or vehicles in the transportation sector, given data availability. One major challenge in developing a module that aims to have a comprehensive representation of the industry sector is gathering techno-economic data, especially with regional differentiation for both the present and future. Table S1 in the Supplement lists all the data sources for the different industries that were used in building up this module for 12 model regions. The details about model regions can be seen in Table S2 in the Supplement. In that sense, we also provide a collection of techno-economic data sources with the open-source release of the module.

This version (version 1.1.0) of the MESSAGEix-Materials module is the first step in an ongoing development process to improve the economy-wide representation of material stocks and flows, industry sectors, and their link to end-use demand. The overall aim is to represent the relations between societies' demands for service provisioning (e.g., building floor space), the required material production and processing, and the associated energy and GHG emissions of industrial production and product stock operation (“stock–flow–service” nexus; Haberl et al., 2017; Wiedenhofer et al., 2024a).

In the remainder of this paper, Sect. 2 provides an overview of the MESSAGEix-Materials module, including the modeling approach (Sect. 2.1); an integrative system definition (Sect. 2.2); the sector-specific representation of iron and steel, cement, aluminum, and petrochemicals (Sect. 2.3); and the demand-side representation in the module (Sect. 2.4). Section 3 presents exemplary results from MESSAGEix-Materials, while Sect. 4 discusses these results, limitations and next steps.

2.1 Modeling approach

MESSAGEix-GLOBIOM refers to a family of global- and country-scoped IAMs developed within the MESSAGEix framework. This framework comprises the MESSAGE linear program (LP) and related tools required to operate the model. MESSAGE is a generic formulation of a least-cost optimization problem representing an abstract energy–economic–environmental system; it can (must) be parameterized to create models with any scope or resolution. The MESSAGEix-GLOBIOM model family parameterizes this generic LP with specific sets of technologies, spatial regions, time periods and so forth. MESSAGEix is maintained and distributed as the open-source Python package message_ix (https://docs.messageix.org/, last access: 29 July 2024), with the core LP being implemented in GAMS. This package also includes the MACRO CGE model, which can optionally be parameterized and solved iteratively with MESSAGE as MESSAGE-MACRO to represent demand responses to changing commodity prices. The package message_ix_models (https://github.com/iiasa/message-ix-models, https://docs.messageix.org/projects/models/en/latest/, last access: 29 July 2024) is another open-source Python package that provides tools to (a) build, (b) solve, and (c) post-process or “report” solution data for models in this family.

MESSAGEix-Materials is published as a module within this message_ix_models package. Using this module, any base model in the MESSAGEix-GLOBIOM family can be augmented with additional structural detail related to industry sectors, as described in Sect. 2.3, and with data matching the resolution and parametrization of the base model. The MESSAGE LP is then solved with this added structure and these added data; subsequently, additional post-processing routines derive quantities of interest from the granular, full-resolution solution data. The same modular approach is used to derive MESSAGEix-GLOBIOM variants with enhanced detail in the water–energy–land nexus (Awais et al., 2024), building and transport domains.

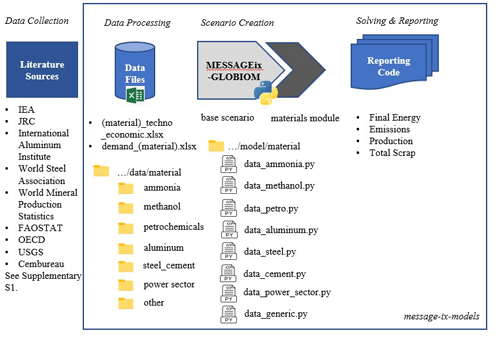

Figure 1 demonstrates the modeling approach and the workflow. Relevant techno-economic data of industry technologies are collected from various literature sources found in Table S1 in the Supplement; these are either stored in spreadsheet format or directly processed via Python scripts. A MESSAGEix-GLOBIOM scenario is used as a base to build a scenario with the MESSAGEix-Materials module. One of the important advantages of this approach is that it enables easy integration with different MESSAGEix-GLOBIOM variants that have different spatial resolutions, including country models (e.g., Orthofer et al., 2019) and different regional resolutions covering 11, 12 or 14 regions. The example scenarios presented in Sect. 3 use the 12-region global model. The material module consists of scripts to process and prepare the model input data for all model parameters. In the final stage, the model is solved together with all the equations of the MESSAGE-GLOBIOM model in an integrated way. The energy system consists of all the extraction and fuel conversion technologies from the primary energy level to the final energy level. The new industry sector technologies that are added from the material module use energy from the final energy level as input to produce material outputs. The reporting code produces a reporting output that is used for analysis. In addition, the integration of MESSAGEix-Materials into the current MESSAGEix-GLOBIOM can be seen in more detail in Fig. S1 in the Supplement.

Representing the material flows for the power sector technologies requires changes in the model formulation because version 3.7 of message_ix does not endogenously consider the flow of material commodities linked to installing and retiring energy technology capacities during construction and retirement in the COMMODITY_BALANCE equation (https://docs.messageix.org/en/stable/model/MESSAGE/model_core.html#auxiliary-commodity-balance, last access: 29 July 2024). To endogenize material stocks and flows, the equation system of the MESSAGEix modeling framework was adjusted so that commodity flows are triggered not only by technology activities during the operational phase but also by the construction, maintenance and decommissioning of the technology capacity. This change in the equation system mostly affects the commodity balance equation and requires adding several parameters for the material demand and release intensities. Further descriptions of the modification of the equations and the newly added parameters can be found in Fig. S2 in the Supplement.

2.2 Integrative system definition

In traditional energy system modeling, the primary focus lies on the energy commodities that serve as inputs to various socio-economic processes and their implications for GHG emissions. Energy commodities are measured in energy units and are traced from the extraction of primary energy carriers which then undergo transformation processes to become useful energy. Any energy losses along the supply chain and in the use phase, e.g., wasted heat, typically go unreported as they dissipate, but these could be reconstructed as residuals from the tracked energy flows. At the same time, flows of carbon and other GHGs are tracked in a thermodynamically correct, mass-balanced manner because a key objective of energy system models is to analyze GHG emission reduction strategies (Dodds et al., 2015; Herbst et al., 2012).

To address the mitigation potentials of material-oriented strategies such as the circular economy and material efficiency, it becomes necessary to expand the scope of this energy-focused model towards fully covering material cycles and the dynamics of material stocks (Pauliuk et al., 2017). For this purpose, we draw on the field of industrial ecology, specifically material flow analysis (MFA), which is widely used in the context of resource and waste management (Graedel, 2019), as well as in quantifying economy-wide resource use in accordance with the system boundaries of the System of National and Environmental Accounts (Eisenmenger et al., 2020; Krausmann et al., 2017). MFA is based on the concept of social metabolism, conceptualizing society as socio-ecological “organisms”, requiring inputs of material and energy to build up, sustain and reproduce their biophysical stocks of people, livestock and non-living material stocks, thereby producing waste and emissions (Fischer-Kowalski and Hüttler, 1998; Gerber and Scheidel, 2018). In recent years, dynamic MFA has increasingly been used to implement a systemic, economy-wide perspective and to simulate stock–demand-driven scenarios or inflow–supply-driven scenarios, assessing the technical and/or physical potentials and limits of material efficiency and circular-economy strategies, e.g., lifetime extension, light weighting, reuse, recycling and downsizing (Hertwich et al., 2019; Worrell et al., 2016; Wiedenhofer et al., 2019; Lanau et al., 2019). The conservation of mass is the fundamental principle in MFA, which entails accounting for all byproducts and waste flows occurring throughout material cycles, from extraction to industrial processing, use as stocks and end-of-life material flows (Graedel, 2019). This means that all material inputs into a system over a certain time period have to be equal to all outputs over the same period, plus/minus stock changes. A clear system definition covering system boundaries, as well as processes and stocks and flows, is indispensable for ensuring compliance with the mass balance principle. A general material cycle system definition in economy-wide material flow analysis and additional information about the methodology can be seen in Fig. S3 in the Supplement.

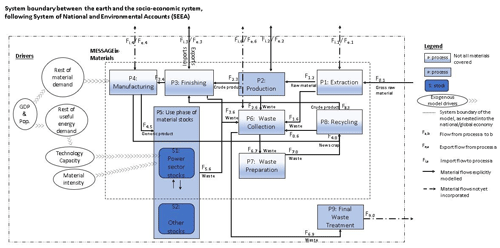

Combining energy system modeling with economy-wide material flow analysis requires focusing on aspects which, so far, have not been considered to be essential in traditional energy system modeling. Therefore, we created a conceptual framework that outlines the targeted system boundaries of MESSAGEix-Materials within the physical Earth system and the socio-economic system as commonly defined in the System of National and Environmental Accounts. In the conceptualization of the model and the definition of system boundaries, we draw on the latest literature and developments in economy-wide material and energy flow analysis (Plank et al., 2022; Wiedenhofer et al., 2024a; Pauliuk and Hertwich, 2015). Version 1.1.0 of MESSAGEix-Materials is a proof-of-concept implementation of the conceptual framework presented in Fig. 2. The figure shows the modeling of industrial and end-use processes () where material flows and stocks for cement, aluminum, steel and primary chemicals (ethylene, propylene, benzene, toluene, xylene) occur and are transformed from raw materials into products and waste. All the components seen in Fig. 2 within the system boundary of MESSAGEix-Materials are endogenously implemented in the model, but there are exceptions for some materials. These are explained at the end of this section. More details about the material flows, the mass balance equations and the corresponding material levels that are used to represent the flows in MESSAGEix-Materials in line with the energy system modeling (see Sect. 2.3) are described in Table S3 in the Supplement.

In MESSAGEix-Materials, material demand for products drives industrial production of materials which accumulate as stocks, similarly to the approach used in other IAMs (Deetman et al., 2021). The drivers of the modeled demand are presented on the left-hand side of Fig. 2. Overall, the combination of exogenous and endogenous demand determines the quantity of materials needed to produce material product stocks, which, in turn, determines raw-material extraction quantities. The raw-material extraction process (P1) is defined in economy-wide material flow accounting principles (Eurostat, 2018; UNEP, 2023), and it represents the process of extracting natural resources such as non-metallic minerals, ores, biomass and fossil energy carriers from natural deposits, which are then further processed and traded (Plank et al., 2022). The model offers an example representation of detailed extraction processes through its implementation of the extraction of fossil fuels (https://docs.messageix.org/projects/global/en/latest/energy/resource/fossilfuel.html, last access: 29 July 2024) such as coal, gas and oil, which can be traded and are subsequently utilized as feedstocks in the chemical industry. The representation considers physical, technical and economic resource availability; the costs at which raw material can be brought to the surface; and the losses and wastage that occur during raw-material extraction. Following the extraction phase, the raw materials move on to the production stage (P2), where detailed production technologies specific to each industry are explicitly represented. In this stage, the material and energy inputs related to the production process are provided together with production costs and emission factors. A more comprehensive explanation of this phase can be found in Sect. 2.3 for each material. Subsequently, there is the finishing phase (P3) and then the manufacturing (P4) phase, which, together, produce generic products that then enter the use phase (P5).

In MESSAGEix-Materials, trade is represented for semi-finished or finished goods for steel, aluminum and chemicals, similarly to how energy commodities are traded in MESSAGEix-GLOBIOM. Each region can export and import through a global commodity pool without specifically tracking bilateral trade flows. Exporting requires “export capacity”, which refers to the infrastructure and logistical capabilities of a region. This is modeled as a pseudo-technology in MESSAGEix. Developing export capacity requires investment costs specific to each traded commodity, while the operational costs of shipping are treated as variable cost components. To determine the trade costs, we use data from the World Bank and the United Nations Conference for Trade and Development (UNCTAD). Additionally, we introduce commodity-specific trade constraints and incorporate historical trade data (see Sect. 2.3) to ensure that each region maintains a minimum degree of self-sufficiency and that the model aligns with current trade flows. We use trade statistics from selected data providers for each bulk material to match trade quantities in the base model year. The data sources used for trade can be found in Sect. S1 in the Supplement. Supply regions are determined based on production and trade costs. If it is cheaper to produce a commodity in one region and to export it from there than it is to produce it locally in another region, the model will opt to export it. The historical capacity for and activity of producing of a commodity are crucial in assessing a region's supply potential. The model includes the historical production and activity data and, therefore, has a representation of the already existing production capacity in the first model years. It also determines when the capacity needs to be retired and when the region needs to invest in new capacity, which will have an impact on the production costs. Additionally, if there is already an established export capacity between two regions, derived from the historical trade data, no extra investment costs are incurred. Future trade projections will follow the same principle, focusing on cost minimization. A more detailed analysis of trade behavior can be conducted in a study with a regional focus by including various cost components, such as import tariffs.

During manufacturing (P4), a fixed percentage of new scrap is formed in the case of metals. This type of scrap requires less preparation before recycling and has a higher quality as it is the direct product of manufacturing. It is usually directly used within manufacturing without going through the market first, unlike old scrap, which is formed at the end of the life of metals. Drivers of the use phase (P5) are explained in more detail below. Once products reach the end of their useful lifetime, they are collected through the waste collection process (P6) and are further distributed, either to waste preparation (P7) and to recycling (P8) or to final waste treatment (P9), where they are not recycled but rather are landfilled or deposited elsewhere. For aluminum and steel, waste (also denoted as old scrap) is distinguished based on scrap quality (Nakamura et al., 2014), forming a scrap supply curve with three different quality levels (1, 2 or 3) without specific end-use distinction. Level 1 is the highest quality of scrap, and level 3 the lowest. Different initial designs and final use conditions of a product determine the ease of recycling, which is reflected in different scrap qualities in the model. Based on a simple supply curve logic, scrap qualities are available in different quantities, where medium-quality scrap (2) is available the most at 50 %, while high- (1) and low-quality (3) scrap are available at 25 %. A minimum recycling rate can be specified for waste collection (P6) of steel and aluminum based on either historical recycling rates or regulatory policies in different regions. The recycling rates in the model can be higher than the specified minimum depending on the economic attractiveness of the recycling options compared to primary material production. In addition, there is a maximum recycling rate imposed to represent the limitations of recycling (e.g., contamination of steel by alloys). The formulation of this representation can be seen in Sect. S7 in the Supplement. During waste preparation (P7), the energy intensity and costs of the preparation for recycling increase as the quality of scrap declines. The lowest-quality scrap (3) requires more technologically advanced sorting and dilution methods to achieve the same quality of recycled metal as the ones produced from high- and medium-quality scrap (1–2). After preparation, scrap is sent to recycling (P8), where it is turned into the final materials to be used in the finishing and manufacturing (P3 and P4) again. During this process, recycling losses (F8.6) are also considered. It is assumed that the recycled materials have the same quality after the recycling process. All the old scrap that is collected in the waste collection stage (F7.8) is used in recycling, assuming the scrap availability and collection rate are the main bottlenecks of the recycling process. Final waste treatments, such as landfilling, incineration or waste-to-energy conversion, are defined as being outside of the system boundaries of the current model version (1.1.0). To maintain the mass balance, all material flows, including waste in its various stages (F1.6, F2.6, F3.6, F5.6, F8.6), can be tracked at each stage by adding relevant reporting variables to the reporting code.

The calculation of material stocks in the model version 1.1.0 differs between the power sector, which is composed of electricity generation technologies, and other sectors, as outlined in Fig. 2 (P5 use phase covering S1 and S2). In the case of the power sector (S1), the capacity of electricity generation technologies in the cost minimization problem is determined by electricity demand, which is driven by energy service demand which is linked to exogenously given population and GDP dynamics, as well as the cost competitiveness of different fuel-to-energy routes. The required material stocks and their associated material flows are then endogenously determined by the modeling framework for the electricity generation technologies. For example, material stock accumulation of the power sector (S1) is determined by the multiplication of the newly built electricity generation technology capacities (e.g., solar panels, hydropower facilities, fossil-fuel-based power plants) and the exogenous material intensities of those technologies (see Sect. 2.4.1). Further details on the modified model formulation used to enable this calculation can be found in Sect. 2.1. Material flows not related to power sector stocks (S2) are determined exogenously in a highly aggregated manner by using GDP and population-driven demand quantities for product stocks. These stocks are then calculated based on this flow and GDP correlation, as described in Sect. 2.4.2. A portion of the manufactured products go into the use phase (P5) and become waste (currently not based on lifetimes but instead based on ratios used in the model), while the remainder can be considered to be stock. For a certain material, that waste ratio is determined by using what is reported in the statistics. This ratio is precisely calculated by dividing overall waste quantity (from both long- and short-lived products) by the total production quantity in the base year (World Steel Association, 2020; IAI, 2020). This base year ratio is used in all years in the model to determine the waste quantity.

Because version 1.1.0 of MESSAGEix-Materials is a proof-of-concept implementation of the novel conceptual framework described above, there are some deviations with regard to how the implementation of the general system definition shown in Fig. 2 is achieved for specific materials and industries which are discussed in Sect. 2.3. For the next versions, we aim to achieve a comprehensive, economy-wide operationalization across all materials and end uses. These deviations stem from the strategic decision to initially prioritize the representation of the most energy- and emission-intensive processes first. These deviations are as follows: first, for non-metallic minerals and metals, we do not fully cover the raw-material extraction and mining phase (P1). Specifically, we exclude the detailed representation of energy use, physical waste and losses during raw-material extraction of gross ores. The raw materials are simply assigned a price tag based on the current market prices for the model base year. This price is discounted in the future at a 5 % rate. For steel, we only use the quantity of the iron ore required to produce one unit of steel in the production process. Similarly, for aluminum, the model only accounts for bauxite extraction quantity as input into the system and represents the refining process. For cement, the quantity of limestone required to produce one unit of clinker is included in the model as the main material input into cement production. However, other non-metallic minerals that are mixed with cement to form concrete, like clay, shale, or sand and gravel, are excluded. Secondly, the current approach only explicitly models product lifetimes for electricity generation technologies, while all other material stock end uses are determined based on a simplified and aggregated approach, as described in Sect. 2.4.2. It is important to note that, due to a lack of data regarding the multitude of chemicals used nowadays, there is no product end-use detail, and, therefore, no stocks are represented explicitly because those chemicals are contained in various products. The only exception is nitrogen fertilizer, which is modeled explicitly; however, it does not accumulate as stock but is purposefully dissipated to the environment. Thirdly, in the waste collection (P6), preparation (P7) and recycling (P8) phases, only metals are modeled, while the end-of-life flows of chemicals and cement are not represented as the recycling and/or down-cycling of cement currently only occurs at very low levels (Cao et al., 2017). Finally, in this version of the model, final waste treatment (P9) technologies, costs and mass balances are not included.

Despite these deviations from the general system definition, MESSAGEix-Materials version 1.1.0 serves as the foundation for future work incorporating further material flows and product stocks as needed for specific research questions related to a particular sector and/or material. This version of the model is, therefore, introduced as a proof of concept, which exemplifies how energy system modeling and economy-wide material flow analysis can be integrated to represent material stocks and flows and their energy requirements and GHG emission implications. As next steps, the extraction and mining phase (P1) can be represented in detail for other materials in a similar way as for fossil fuels (https://docs.messageix.org/projects/global/en/latest/energy/resource/fossilfuel.html, last access: 29 July 2024). In addition, explicit dynamic stock–flow implementations, as for electricity generation technologies, can be introduced to the model to increase the endogenous coverage of other material stocks such as buildings, infrastructure or vehicles. Regarding the end of life, it is possible to extend cement and chemical flows to P6, P7 and P8 by following the same structure as for other materials. For chemicals, plastics need to be represented as an explicit commodity in the model for a better representation of waste treatment options.

2.3 Material supply and processing in reference energy and material system

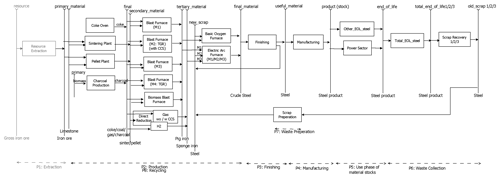

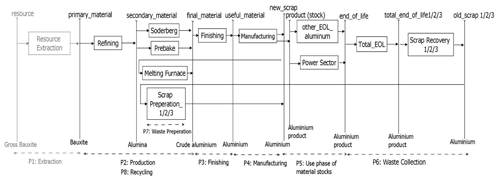

MESSAGEix-Materials includes the explicit representation of technologies and processes from four key energy- and/or emission-intensive material industries: steel, cement, aluminum and petrochemicals. The materials are primarily chosen based on their substantial contributions to final energy uses and emissions in the industry sector (Lamb et al., 2021). In addition, their end-use applications are considered for their potential to be combined with important demand-side strategies such as the ones from mobility, built environments, machinery or packaging. The life cycle representation of different material industries in the model follows a generic structure, as shown in the form of a reference material system, analogous to the common reference energy system representation used in energy system modeling (Beller, 1976), and is customized based on the process-specific differences between industries. A generic reference material system diagram for the model can be seen in Fig. S4 in the Supplement. Differently to Fig. 2, the series of figures that are used throughout Sect. 2.3 provide explicit information on how the processes are modeled in MESSAGEix-Materials for a specific industry. Similarly to the representation of energy commodities in energy-engineering models such as MESSAGEix, depending on the stage of the material's life cycle, materials exist at different levels: primary_material, secondary_ material, tertiary_material, final_material, useful_material, product, end_of_life, and old_scrap 1/2/3.

In Figs. 3, 4 and 5, the use phase and end-of-life phase of the resulting products are represented endogenously for the power sector, while the rest are represented in the generic category “Other_EOL”. The additional step “Total_EOL” collects all the available waste at the total_end_of_life_1/2/3 level based on the scrap quality and availabilities as described in Sect. 2.2. From the waste available at these levels, the model decides how much to use via the scrap_recovery_1/2/3 technologies. Different energy inputs and costs are associated with the scrap preparation 1/2/3 technologies based on the respective scrap qualities. Table S3 in the Supplement shows how levels from reference material system diagrams are connected to the system boundaries and processes from Fig. 2.

This version of the model can be used as a basis to associate different scrap qualities with end-use sectors if they are linked to specific end-use demands and end-of-life flows considering lifetimes, such as for vehicles or buildings. For example, end-of-life vehicles, machinery parts and electronics are the highest sources of copper contamination in old scrap (low-quality scrap), while new cars are the main end use driving the demand for higher-quality steel (Nakamura et al., 2014).

Below, the specific representation per industry sector is explained.

2.3.1 Iron and steel

The iron and steel sector is one of the largest industrial GHG emitters among all bulk material industries. Globally, in 2018, the sector made up 25 % of the total direct industry CO2 emissions at 2.1 Gt yr−1 (IEA, 2020c). Crude steel production in 2019 amounted to 1869 Mt yr−1 (World Steel Association, 2020), and the final energy use amounted to 37 EJ yr−1 in 2020, which makes steel production responsible for 24 % of industrial final energy demand and 8 % of global final energy demand (IEA, 2020c). Steel is used most notably in the construction sector to build buildings and infrastructure, as well as to produce transportation vehicles, machinery and appliances (Pauliuk et al., 2013). In addition, it will be an important material for the energy transition, being used in low-carbon technologies such as solar panels, wind turbines, hydropower and electric vehicles. Global steel demand has increased more than 3-fold since the 1970s with the continuing rapid urbanization and buildup of infrastructure (IEA, 2020c). Steel is produced mainly through two routes. The more dominant practice is through blast furnaces, which produce pig iron from iron ore, and basic oxygen furnaces, which convert molten pig iron into steel by blowing pure oxygen into the charge (BF–BOF process). There is a competing process called DRI–EAF routes (direct-reduction iron and electric-arc furnace), which goes through a direct reduction of iron ore without melting it and uses electricity to smelt the charge and make raw steel. This process using EAF (not necessarily with DRI) has a lower energy use than BF–BOF, which involves energy-intensive processing of raw materials. Also, EAF can be installed in smaller units for different market sizes and can be more economical than BF–BOF because it can fully rely on scrap metal as its input material with the possibility of varying the input mix based on the market situation. While some of the countries with large steel-making capacities like the USA, India and Italy rely heavily on the EAF steel-making process, the BF–BOF is still the dominant technology globally and, especially, in China, which produces more than half of all steel supply globally. Specifically, China produces 90 % of its steel by means of BF–BOF (World Steel Association, 2020).

The MESSAGEix-Materials module implements these two routes while also considering old-scrap recycling inputs into the material production process. The modeled process for the BF–BOF route includes the raw-material preparation step, which involves coke oven and sinter and/or pellet plants. We also represent important low-carbon options in the steel industry in the model, such as carbon capture and storage (CCS) with top gas recirculation in blast furnaces, CCS in natural-gas DRI furnaces, 100 % hydrogen use in DRI furnaces, and replacing coke and coal with biomass in blast furnaces. Top gas recirculation with CCS in blast furnaces involves reusing the gas that exits in the furnace (top gas), which contains significant amounts of CO2, CO and H2. Instead of releasing this gas, it is cleaned to remove some CO2 and then is recirculated back into the furnace. This process not only reduces emissions through carbon capture but also increases energy efficiency by lowering coke consumption. Also, for the natural-gas DRI technology, CCS can be added to capture CO2 emissions. Typically, a DRI technology can operate with up to 30 % hydrogen without modifications (MIDREX, 2022). To use 100 % hydrogen in DRI technology, a retrofit option is added to the model. Finally, we represent the option to replace coke in blast furnaces with biomass either partially or completely. The latter is particularly feasible in smaller blast furnaces, with capacities ranging from 0.06 to 0.4 Mt yr−1, commonly used in Latin America (Fujihara et al., 2005). Figure 3 below shows the reference material system for iron and steel as represented in the model. In the figure, blast furnace mode 1 is the traditional blast furnace, mode 2 is top gas recirculation (TGR) with CCS, while mode 3 and 4 represent the partial biomass substitution. In addition, a separate small-size biomass blast furnace technology is represented; this can operate fully with biomass. DRI technology has different modes, using natural gas either with or without CCS, as well as full hydrogen substitution. For the electric-arc furnace, modes 1 and 3 represent primary production, operating with either coal or gas, while mode 2 is the full scrap-recycling mode.

Iron and steel were the world's ninth most traded products in 2021 in terms of value (OEC, 2022). International trade of iron and steel is also an essential component to understand the technological changes and supply chain dynamics in converting raw materials to finished products. In the model, trade is represented at the useful_material level, which delivers semi-finished steel after the finishing process. Regions can import and export semi-finished iron and steel from a global trade pool. For the calibration of trade, import and export numbers from the World Steel in Figures report by the World Steel Association are used (World Steel Association, 2020).

2.3.2 Aluminum

The aluminum industry mostly causes indirect emissions due to the high electricity demand of its industrial processes. The sector was directly responsible for almost 200 Mt yr−1 of direct CO2 emissions in 2018 (2.3 % of the total industry emissions), and the number goes up to 1 Gt CO2 yr−1 if the emissions from electricity consumption are included (IEA, 2023a). Production amounted to 100 Mt yr−1 in 2020 (IAI, 2020), and the final energy use in 2020 was around 5 EJ yr−1 (3 % of the total industry final energy) (IEA, 2021b).

Aluminum is one of the non-ferrous metals that is widely used in end-use sectors such as transportation, packaging, buildings and consumer goods. The contemporary global aluminum stock in use has reached about 10 % of that in known bauxite reserves, and, still, no clear signs of saturation can be observed (Liu and Müller, 2013). In the context of the transformation to low-carbon energy systems, this plays an important role in strategies such as light weighting in the transport sector or for grid infrastructure expansion, which is required to accommodate increasing renewable-energy technologies (Kalt et al., 2021; Deetman et al., 2021).

The production process for aluminum consists of two main steps: refining and smelting. Refining is the step where the extracted bauxite mineral is converted to an intermediate material, alumina. The decarbonization potential mostly comes from smelting, with a 78 % share of energy consumption within the whole production process (IEA, 2009). In the model, we represent both the refining and smelting steps. Refining takes bauxite as input from an unlimited supply with a relevant variable cost. The second process, smelting, is performed by two commercially available technology options: pre-bake and Soderberg. Pre-bake and Soderberg technologies in aluminum production differ in terms of anode manufacturing and usage. Pre-bake technology uses pre-baked, solid carbon anodes that are inserted into the electrolytic cells, offering higher energy efficiency due to better control over anode quality and cell conditions. In contrast, Soderberg technology involves continuously self-baking anodes from a paste added periodically, resulting in lower energy efficiency and higher operational costs. This technology is mostly used in locations where there is still existing capacity, with few new capacity additions. Both technologies require significant electricity inputs ranging from 13 to 17 kWh kg−1, which makes the primary energy intensity and indirect emissions very dependent on the energy mix of a certain region. The liquid aluminum is then converted into the final product in the finishing and manufacturing processes.

The melting-furnace and scrap preparation technologies enable the usage of old and new scrap as an alternative production path to smelting. Secondary production has an energy requirement per tonne of aluminum around 10 times lower than that of primary production (Gautam et al., 2018). Figure 4 shows the production processes for aluminum as represented in the model. The trade of aluminum is represented at the product level because finished aluminum from the manufacturing process is the most traded form of aluminum (IAI, 2020). Regions can import and export finished aluminum at the product level from a global trade pool. To calibrate regional aluminum trade flows, we use data from the International Aluminum Institute, which reports material cycles from 1962 to 2021 (IAI, 2020).

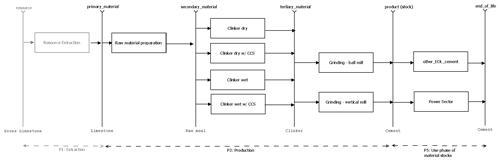

2.3.3 Cement

While cement production consumes less energy than steelmaking, it is one of the most emission-intensive industries, amounting to 2.3 Gt CO2 yr−1 in 2018, equating to 27 % of total industry emissions (IEA, 2020b). In 2020, cement production amounted to 4100 Mt yr−1, with a global thermal energy use intensity of 3.55 GJ t−1 (IEA, 2023c). Cement is widely used in buildings and infrastructure developments, such as bridges or dams, and, due to ongoing urbanization and increasing affluence around the world, the demand for cement is expected to increase (Cao et al., 2017). About 60 % of the emissions from cement production come out of a chemical process called calcination (Kermeli, 2016). Calcination is a process used to remove carbon as carbon dioxide from limestone (calcium carbonate, CaCO3) by heating it. This process happens in kilns, where raw-material inputs (called “raw meal”) are heated to form clinker. Clinker is then ground with gypsum in a mill, and this then becomes the end product, cement. Two commercially available options to make clinker are included in the model: dry and wet processes. The wet process receives a wet mixture of washed raw materials, which consumes more energy to dry the materials. Two technologies are included in the model for the grinding process: a ball mill, which is more conventional, and a vertical mill, which is more energy-efficient for a higher cost. CCS options for the clinker-making stage are added to the model, given the importance of the technology for decarbonization of the industry. Figure 5 shows the reference material system for cement as represented in the model.

Cement is usually only traded at low levels compared to other commodities, mainly because of the high cost of road transport and the weight of the commodity, usually making it not worthwhile to transport it over long distances. Global cement trading does account for 6 %–7 % of production, most of which is transported by sea and is usually used to balance out surpluses and shortages. Road deliveries of cement generally do not exceed distances of 150 km (European Commission, 2001; Akram, 2013). Because MESSAGEix-Materials operates in 12 world regions, it is not possible to represent the local, intra-country or intra-region trade flows. Due to this reason and the low overall trade volumes, cement trade is not represented in the model version 1.1.0.

Gray sections indicate those parts of the economy-wide material cycles currently not represented in model version 1.1.0.

2.3.4 Petrochemicals

The chemical and petrochemical industry accounts for 14 % of total industry CO2 emissions, which amounted to 1.2 Gt CO2 yr−1 in 2018 (IEA, 2020b). In 2020, the final energy use, including feedstock use, reached 48 EJ yr−1, representing 30 % of the industry's total final energy use (IEA, 2020a). Petrochemicals, a subset of chemicals derived from petroleum (oil) products such as naphtha or from natural gas such as ethane, were responsible for 90 % of the total feedstock demand in chemical production in 2018 (IEA, 2018). Almost half of the energy inputs into the sector are for feedstock use, which implies that there are fewer CO2 emissions emitted from industrial processes compared to from the steel and cement sectors and that an important proportion of carbon remains in the final product.

Despite the complexity of the chemical sector, there are seven primary chemicals that provide the key inputs on which the bulk of the chemical industry is based. These primary chemicals are ammonia, methanol and high-value chemicals (ethylene; propylene; and, shortly known as BTX, benzene, toluene and mixed xylenes), which account for approximately two-thirds of the sector's total consumption of final energy products (IEA, 2018). In 2020, the production of these primary chemicals reached 543 Mt yr−1 (IEA, 2021a, 2018; Methanol Institute, 2022).

In the model, carbon contained in the chemical and plastic products is represented under the following assumptions. We differentiate products that are oxidized during use and long-lived non-oxidizing products by drawing on the NEAT model, which differentiates chemical products based on their chemical stability during use (Neelis et al., 2005). In addition, we make use of the ratios of primary chemicals that end up in plastics and the share of the plastics that go to incineration. A total of 85 % of the high-value chemicals and 65 % of methanol are used in the production of plastics (Levi and Cullen, 2018). We use the plastic waste treatment projections of Geyer et al. (2017) to consider the CO2 emissions from waste incineration. According to these projections, 28 % of the plastics are incinerated in the base year 2020, and it is assumed that the incineration percentage will increase to 50 % by 2050 (Geyer et al., 2017). The carbon that does not end up in plastics (released due to oxidation during use, e.g., solvents), the carbon released because of incineration and the carbon lost in steam cracking are released into the atmosphere during the emission accounting. The rest of the carbon is treated as being stored within material product stocks and is therefore not accounted for in the chemical sector emissions.

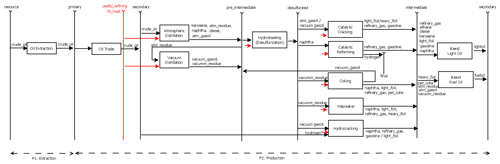

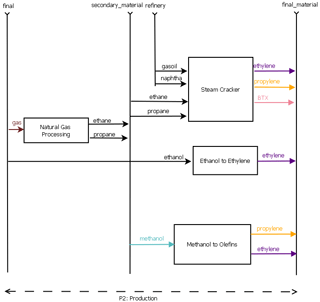

High-value chemicals

The production of ethylene, propylene and BTX, jointly referred to as high-value chemicals (HVCs), amounted to around 360 Mt yr−1 in 2018 (IEA, 2018). HVCs are the main building blocks of plastics that are used in various end uses, ranging from packaging and consumer goods to the insulation of buildings. Refinery products are the most important feedstock needed to produce high-value chemicals. Therefore, the refinery representation is extended in the material module to represent these intermediate products. Figure 6 shows the reference energy system for the extended refinery representation as represented in the model. Refineries can vary in terms of their structure and specific processes in different regions. In MESSAGEix-Materials, we represent a typical crude oil refinery reflecting the current operating refineries in North America based on the PRELIM model (Abella et al., 2020). The processes that are represented include atmospheric and vacuum distillation, hydro-treating, catalytic cracking, catalytic reforming, coking, visbreaking and hydro-cracking. The intermediate products of the refinery process are light and heavy fuel oil, naphtha, atmospheric and vacuum gas oil and residues, kerosene, diesel, gasoline, refinery gas, and petroleum coke. These products can be used as feedstock in the chemicals industry, while the remainders are blended into two simple commodities, namely light oil and fuel oil, based on their densities. Products that are not explicitly represented in the refinery are lubricants, bitumen (it is part of vacuum distillation residue but is not a separate commodity) and paraffin waxes. Pre_intermediate, desulfurized and intermediate are levels added to represent the refinery products at their different stages.

Extending the refinery process enables a detailed representation of the production of HVCs. The steam cracker is the main conventional technology that can use different feedstocks in different modes. In the model, the feedstock alternatives for the steam cracker are two different types of gas oil (atmospheric and vacuum), naphtha, ethane or propane. Each of these primary feedstocks results in the composition of HVCs with different ratios. Gas oils and naphtha are the products of the detailed refinery representation in the model, while ethane and propane are formed by a natural-gas processing plant. Production of ethylene from bio-ethanol is also included as a renewable production option. Bio-ethanol is supplied by ethanol synthesis via biomass gasification. The production pathways for HVCs as represented in the model are shown in Fig. 7. In addition, the methanol-to-olefins (MTO) process is represented; this produces high-value chemicals and is explained in more detail below in the Methanol section. Trade is represented for high-value chemicals as a single commodity at the useful_material level. For the calibration of trade, an enhanced data set (BACI) of the UNSD Comtrade is used, and the products that belong to the HVC group are aggregated for MESSAGEix regions (see Sect. S1 in the Supplement). Also, a global cap is implemented for the trade volume of HVCs at a maximum of 20 % of the production for all optimization years. This is because the feedstocks for HVCs are traded more widely than the HVCs themselves.

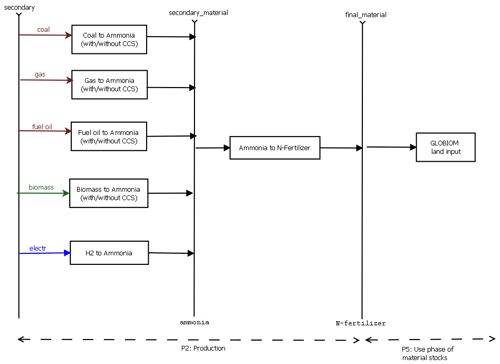

Ammonia and nitrogen fertilizer

Global ammonia production for both fertilizer and industrial applications was 185 Mt yr−1 in 2020. In the same year, production was completely fossil fuel based, with 72 % originating from natural gas, 26 % originating from coal and the remainder originating from oil (IEA, 2021a). Ammonia is an input to all nitrogen fertilizer production processes. Among the nitrogen (N) fertilizer products, urea-based fertilizer with a high nitrogen content is widely used (58 % of all N-based fertilizers in 2015) due to its high nutrient concentration and relatively low cost (Yara, 2018). The rest of the use cases for ammonia include cleaning products; refrigeration and air conditioning; the production of plastics, textiles, explosives, and food and beverages; and pharmaceuticals. In addition, the use of ammonia as a fuel is promising as a carbon-free energy carrier produced via renewable sources which can be used in various applications, from power generation to transportation. However, there are various technical, safety and environmental challenges to be addressed before it can be adopted widely. The potential end use of ammonia as a fuel is currently not explicitly represented in the energy system model of MESSAGEix-GLOBIOM. Therefore, MESSAGEix-Materials version 1.1.0 only covers the non-fuel use of ammonia.

MESSAGEix-Materials currently represents ammonia and N fertilizer production processes with five different feedstock sources, including coal, gas, biomass, fuel oil and hydrogen via electrolysis. In addition, all the technologies using carbonaceous feedstocks can be built with carbon capture and storage (CCS) technology. As we are not interested in the detailed material cycle of nitrogen, we do not represent specific types of N fertilizers but rather treat them as a representative commodity type. For the trade implementation, currently, MESSAGEix-Materials implements the trade of final N fertilizer (about 30 % of its production is traded globally) and the intermediate product ammonia (about 10 % of global production is traded) (IEA, 2021a). The trade calibration has been conducted with a methodology and data sources identical to those used for HVCs. In addition, GLOBIOM models the production, consumption and trade of the agricultural products. Figure 8 shows the reference material system for ammonia as represented in the model.

Methanol

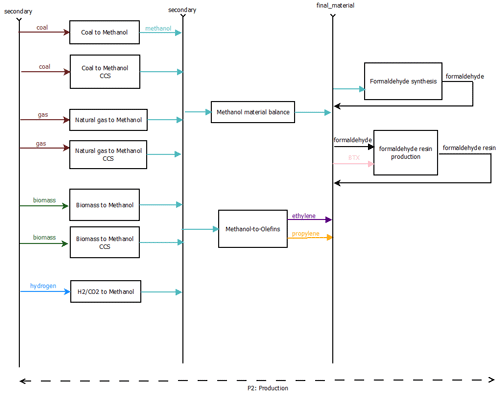

Methanol is the third major base chemical of the petrochemical sector, with production that was just above 100 Mt yr−1 in 2020 (Methanol Institute, 2022). Feedstock options are currently dominated by natural-gas steam reforming and coal gasification. Coal gasification plants exist only in China, which produces half of the global methanol supply due to the country's large methanol capacity. In MESSAGEix-Materials, various feedstock options are implemented, including fossil (natural gas and coal) and low-carbon options with or without CCS. Low-carbon feedstocks are covered in the model with two technologies utilizing either biomass or syngas from hydrogen with captured carbon dioxide from CCS plants. In recent years, the production route of methanol to olefins (MTO) has overtaken traditional chemical products as the single biggest methanol consumer. This technology is currently almost exclusively used in China, consuming around 25 % of methanol production in China (Methanol Institute, 2022). Therefore, we include methanol-to-olefins technology in the model, which produces propylene and ethylene, featuring an alternative pathway to traditional oil-based petrochemistry. The second biggest share of methanol production is used to produce formaldehyde resins, which are mainly used in engineered wood products. The production of formaldehyde and the subsequent resin production are explicitly represented by individual technology instances. This enables the endogenization of methanol demand coming from the construction industry for future applications of the model despite the fact that it is not included in this model version.

Besides traditional chemicals and MTO, a significant amount of total methanol production is used in various fuels. Besides direct fuel blending of methanol, the two major fuel-related applications of methanol are methyl tert-butyl ether (MTBE) and biodiesel production. MTBE is a gasoline additive that increases combustion properties, and it is currently the most important substitute for lead as an anti-knocking agent. The second use case is biodiesel, mostly produced via the trans-esterification of fatty acids with an alcohol. With methanol being the cheapest available alcohol, it is the most used alcohol for biodiesel production. The emerging methanol demand for these use cases is endogenously modeled in MESSAGEix-Materials by setting region-specific input shares for methanol in the MESSAGEix-GLOBIOM transport sector based on regional MTBE and biodiesel consumption. For an explicit representation in MESSAGEix-Materials, the methanol production technologies can operate in “fuel” or “feedstock” mode. The two modes are modeled with identical technical parameters and only serve the purpose of being able to report methanol supply for energy and non-energy uses separately. Figure 9 shows the reference material system for methanol as represented in the model.

Methanol is globally traded at high volumes, with South America and the Middle East being the major exporting regions at present. The trade calibration is done in the same manner as for HVCs and uses the same data sources.

2.4 Material demand

The demand for materials within MESSAGEix-Materials is determined in two different ways, depending on the end-use sectors. Section 2.4.1 explains the end-use sectors where material demand is endogenously generated by different parts of the model, such as the power sector's material stock demand, the demand for nitrogen fertilizer and the explicitly modeled uses of methanol described in Sect. 2.3.4. For the other demand categories, the process of deriving material demands from GDP projections exogenously is elaborated in Sect. 2.4.2.

2.4.1 Endogenous material demand

Electrification is an important element of the transformation to a low-carbon energy system, and, in general, many low-carbon electricity generation technologies, particularly those based on renewable energy sources, have higher material demand per unit of installed capacity and, in particular, per unit of electricity generated compared to conventional thermal power plants (Arvesen et al., 2018). To incorporate this important linkage, we add material intensities for the most energy-intensive bulk materials used in power plant construction – steel, cement and aluminum – to the MESSAGEix-Materials module. We rely on data from life cycle analysis (LCA), specifically designed for use within IAMs such as MESSAGEix-Materials (Arvesen et al., 2018; Kalt et al., 2021). Upon the construction of power plants, demand for the three bulk materials is generated endogenously based on the material intensities in Arvesen et al. (2018) and Kalt et al. (2021) for hydropower per generation technology, vintage and region. Power sector material stocks exhibit specific lifetimes, and upon the retirement of the capacity, end-of-life waste material is released, which is then collected and becomes available for recycling or goes into final waste management. Flows related to operation and maintenance are not included in the scenarios for this paper, though it is possible to investigate these flows as a result of the model developments described in Sect. 2.1.

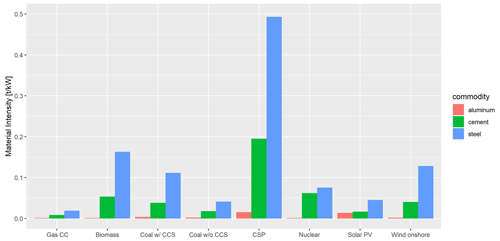

Figure 10Illustration of bulk material intensities for a subset of the electricity generation technologies in MESSAGEix-Materials. Data are shown for western Europe in the year 2030. Source: “mix” and “residue” technology configurations from Arvesen et al. (2018). Gas CC refers to gas combined cycle, CSP refers to concentrated solar power, and solar PV refers to solar photovoltaics.

Figure 10 provides an overview of material intensities (tonnes per capacity of the power plant) for an illustrative subset of the electricity generation technologies in MESSAGEix-Materials. As can be seen, on average low-carbon energy technologies tend to have larger material intensities than conventional generation technologies. However, two things should be noted in this context (Kalt et al., 2021): (i) there is a significant spread, with material intensities varying by 1 order of magnitude among the groups of low-carbon and conventional generation technologies, and (ii) material intensities per unit of installed capacity need to be put into the context of total possible energy generation, which depends on the operation time of the specific power plant. These ratios (material intensity to total operation time) also vary considerably among the technologies, with illustrative full-load hours ranging from 1000 h yr−1 for onshore wind or solar photovoltaics (PV) under less favorable conditions to potentially more than 8000 h yr−1, at which level many nuclear power plants are operated. These factors are already taken into account in the energy system model MESSAGEix-GLOBIOM when deciding on a cost-effective electricity generation mix under different climate targets.

It is important to note that, overall, in 2015, the material stocks of power plants were small compared to the total economy-wide material stocks (Kalt et al., 2021). Per material group, power plant stocks make up for 1 %–2 % (aluminum and steel vs. all metals) and 1 %–3 % (concrete) of the economy-wide material stocks estimated by Krausmann et al. (2018). However, it is still useful to endogenize these flows in the model for two reasons: firstly, to investigate whether the share of stocks undergoes a significant change with the increasing electrification under stringent climate policy; secondly, as power sector technologies are already part of MESSAGEix-GLOBIOM, it is a good starting point to test new model functionalities for linking material flows and technology capacities. This same functionality, which is described in Sect. 2.1 in more detail, can be used to endogenize other material stocks that constitute a larger fraction. Data on the end uses of stock-building material flows suggest that the majority of these materials are used in the construction of buildings, infrastructure and other machinery (Liu and Müller, 2013; Pauliuk et al., 2013; Cao et al., 2017; Wiedenhofer at al., 2024b).

The second end-use sector in which the material demand is endogenously represented is nitrogen fertilizer demand. For the N fertilizer demand projections, we use the MESSAGEix-GLOBIOM emulator and import its synthetic fertilizer demand projections directly. Fertilizer demand in GLOBIOM is driven by future agricultural demand for food, feed or other uses including bioenergy. The current implementation of the emulator includes a set of land-based climate mitigation scenarios, as well as a representation of selected land-use-related Sustainable Development Goals (SDGs) such as moving towards low-meat diets and halving food waste, which all affect future nitrogen fertilizer demand (Frank et al., 2021).

Finally, the methanol demand for the methanol-to-olefins route is linked to the exogenous high-value-chemical demand through the MTO technology. The methanol demand for fuel applications is driven by the demand for oil products in the transport sector or the demand in industry as fuel based on the choice of the model.

2.4.2 Exogenous material demand

Regional demands in relation to the total material demand for the three materials – steel, cement and aluminum – are projected exogenously following the method suggested by van Ruijven et al. (2016). This method chooses a best-fitting functional shape for the demand projection curve driven by per capita GDP, which, empirically, is observed to have a saturating behavior for each country. With the data being extended with more observational years, we estimate updated curves for the three materials. We have found, similarly to van Ruijven et al. (2016), that a globally non-linear model (NLI) with an S-shaped relation between GDP per capita and material consumption fits best for the cement and aluminum (see Eq. (1)) and that a variant in which per capita material demand is reduced over time as a result of efficiency improvement (NLIT) fits best for steel see (Eq. (2)). The global consumption curve is used as a starting point, and individual curves are derived for major steel-producing regions. The global curve for each material is calibrated to match the historical demand values for each region by modifying the maximum in the per capita consumption (PCC) curve (B) and the per capita saturation level (a) parameters. In the formulations in Eqs. (1) and (2), T represents time, and C represents per capita consumption.

This method is chosen as it can provide a first-order projection of economy-wide material flows and allows us to fully cover the industry's energy demand resulting from those flows. However, the ultimate goal is to reduce the share of material demand that is currently exogenously derived. This can be achieved either directly in MESSAGEix-Materials, as was done in the power sector, or by integrating the model with other end-use sector models, for example, for transportation and buildings by linking to MESSAGEix-Transport or MESSAGEix-Buildings (Mastrucci et al., 2021). The benefits of making more of the material demand endogenous are discussed in Sect. 4.

Due to lack of comprehensive historical data for petrochemical demand, applying the same method as that which is explained above was not possible. Instead, we rely on a methodology that uses IEA projections for high-value chemicals and the residual demand for methanol and ammonia (which can be used as fuel) that are not covered by endogenized demand drivers. The IEA projections are modeled by using regional GDP and historical demand intensity (IEA, 2018). However, the underlying data are not publicly available. Therefore, to account for differences in long-term GDP trajectories, we use the implicit income elasticity of the IEA demand projections and the GDP projections from the “middle-of-the-road” Shared Socio-economic Pathway (SSP2) (Dellink et al., 2017) to project the future chemicals demand in the model.

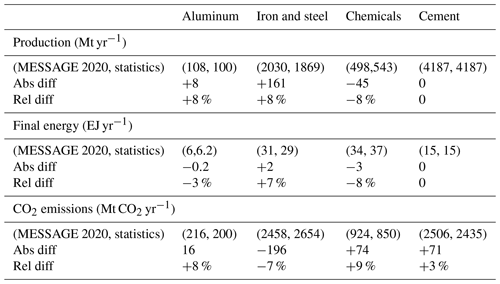

3.1 Comparison of base year results with statistical data

To validate the results, model values are compared with the reported statistical values of 2020 from different sources, mainly IEA. More specific information on the sources for this comparison is listed in Table S4 in the Supplement. Final energy, CO2 emissions and production values calculated with MESSAGEix-Materials are compared to statistics for the year 2020, as shown in Table 1. For the model validation purposes, we consider a deviation of ±10 % to be acceptable and within statistical uncertainties. For example, CO2 emissions from fossil fuel combustion and industrial processes according to the IPCC are known, with an accuracy of about 8 % (90 % confidence interval; IPCC, 2023). In the section below, we explain the reasoning behind some of the variations.

Table 1Comparison of MESSAGEix-Materials 2020 results with reported statistics. Numbers are rounded to the nearest integer.

The relative differences in production levels (±8 % for aluminum, iron and steel, and chemicals) can be explained as follows. For steel and aluminum, the material demand inputted into the model represents the final product, which includes losses from the manufacturing and finishing phases. However, the production figures reported by the model are based on crude material, which has not undergone further processing. As a result, there may be discrepancies between the model's output and statistical data, depending on the average loss rates used in the model. As for the chemicals, some of the demand is determined endogenously; therefore, there can be slight variations between the model values and numbers reported in the statistics. In the case of cement, the demand is provided exogenously to the model, and the cement production exactly matches this number.

There are also variations in the levels of final energy use and CO2 emissions. These differences are primarily due to variations in system boundary definitions. For the chemical industry, emissions and final energy statistics are collected from various sources for different chemicals. To compare these statistics with model results, we perform calculations to establish a system boundary that aligns with the model's framework. For example, the International Energy Agency (IEA) reports the final energy use for all chemicals. We adjust this by multiplying their value with the share of primary chemicals in the final energy use to obtain a number that is comparable to our model values. A similar calculation is done for emissions to exclude the portion that results from the production of methanol that is used as fuel and not in chemical industry. These adjustments ensure that our model results are within a reasonable range of emissions, typically with a difference of less than ±10 %.

Iron and steel constitute one of the industries where accounting for the final energy and emissions is more complex. MESSAGEix emissions and final energy values include the coke and coal inputs into blast furnaces, which are partly converted to blast furnace gas. The compared IEA final energy values are calculated from the IEA energy balances to only include blast furnaces and exclude coke oven energy consumption. CO2 emissions are calculated by using the CO2 intensity value reported by IEA, which does not clearly state which part of the steel system boundary is included in the direct CO2 intensity.

In addition, it is important to note that some statistics are not exactly for the year 2020 but are instead for 2018 or 2019, such as aluminum emissions statistics, which are reported for 2018, while the production value is from 2020. This can also cause some differences between the model and statistics values. Table S4 in the Supplement shows more details on all these aspects.

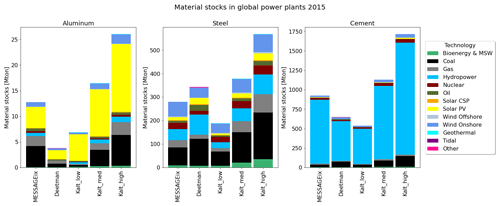

3.2 Comparison of power sector material stocks with the literature

Figure 11 compares the estimates of the material stocks in global power plants for MESSAGEix-Materials with the studies of Deetman et al. (2021) and Kalt et al. (2021). Over all generation technologies and materials, the estimates of total power plant material stocks are mostly within the same order of magnitude but differ by up to a factor of 3 across studies (Fig. 11). This discrepancy is due to differences in the utilized values for two parameters: the installed generation capacities and the material intensities used for power plant technologies. Total installed capacity differs by 3 %–17 % between studies (Table S5 in the Supplement). Per technology, differences range from virtually zero (for solar CSP) up to 61 % (for bioenergy and municipal solid waste (MSW)). Capacity differences in MESSAGEix compared to the other sources are a result of model calibration to electricity generation instead of generation capacity. The differences in capacities are small when compared to variations in assumed material intensities (Table S6 in the Supplement). Across the five estimates in Fig. 11, material intensities per technology differ between a factor of 2 for cement in gas plants to a factor of 24 for cement in solar CSP plants. Large differences of over a factor of 10 are found for the material intensities of aluminum in gas, coal, nuclear and bioenergy, and MSW plants. Overall, the largest absolute differences manifest for aluminum stocks in solar PV due to a combination of capacity differences of up to 27 % and material intensity differences up to a factor of 6, as well as cement stocks in hydropower plants with capacity differences of up to 13 % and material intensity differences up to a factor of 3. Despite the observed large differences in the material intensities of plant technologies, the absolute estimates of almost all of the technology-specific material stocks from MESSAGEix-Materials are clearly within the range of the other two literature sources.

Figure 11Material stocks in global power generation technologies in 2015 based on this work (MESSAGEix-Materials) and on the work of Deetman et al. (2021) and Kalt et al. (2021). The three estimates (low, med, high) by Kalt et al. (2021) result from using low, medium and high material intensity assumptions as derived from the literature. The technology categories in the figure differ slightly from those of MESSAGEix-Materials due to the mapping of all three data sources to a common technology set. Similarly, the comparison shows cement instead of concrete stocks. To convert concrete into cement stocks for the Deetman et al. (2021) and Kalt et al. (2021) results, a cement content of 15 % in concrete was assumed. MSW refers to municipal solid waste, CSP refers to concentrated solar power, and PV refers to photovoltaic. For figure data, please see Table S7 in the Supplement.

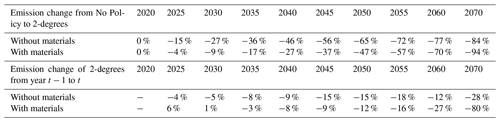

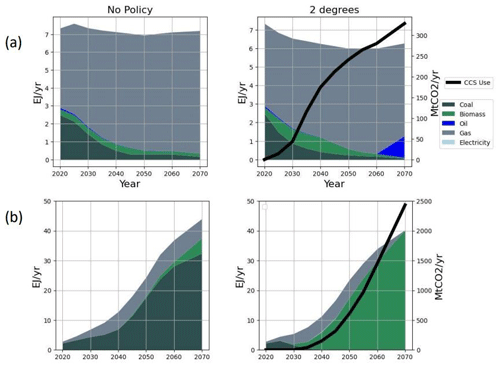

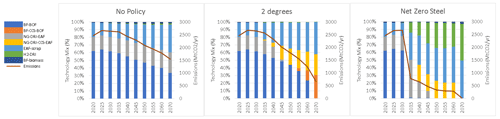

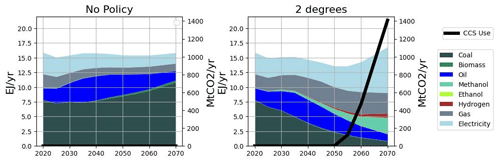

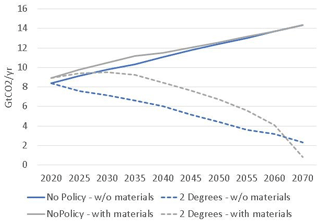

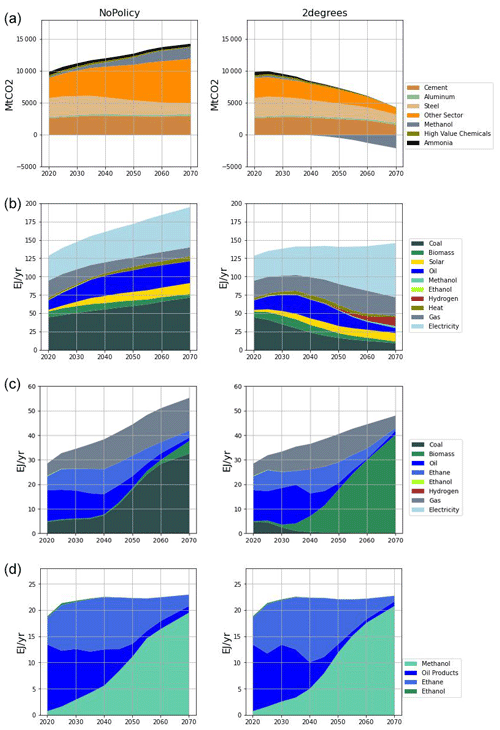

3.3 Scenario comparison

The model results are compared for the two illustrative scenarios “No Policy” and “2-degrees”, more specifically for the newly added industry sectors until the year 2070, the time at which total CO2 emissions roughly reach net zero. No Policy is a baseline scenario without any additional policy constraints beyond developments until 2020 and thus serves as a counterfactual scenario, whereas the 2-degrees scenario aims to limit global warming to 2 °C by the end of the century. The 2-degrees scenario uses global uniform carbon prices from a 1000 Gt CO2 “full century budget” scenario in line with 2 degrees (Riahi et al., 2021). A full century budget setup permits the budget to be temporarily overspent, as long as net-negative CO2 emissions bring back cumulative CO2 emissions to be within the budget by 2100.

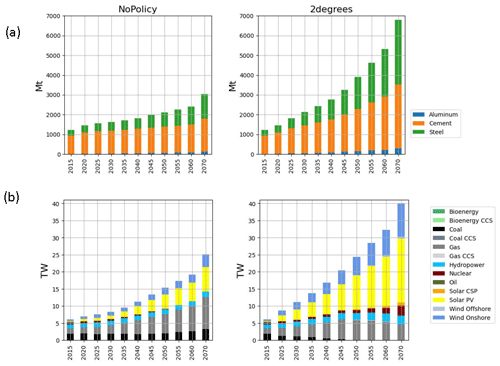

3.3.1 Demand side

Currently, MESSAGEix-Materials derives the demand for materials either endogenously or exogenously, as explained in Sect. 2.4. The following section provides results on material demand and stocks from the power sector as endogenously represented in MESSAGEix-Materials (see Sect. 2.4.1). Figure 12 shows the material stocks and technology capacities by comparing the No Policy and 2-degrees scenarios. Because of the increased electrification, the overall capacity of electricity generation technologies increases in the 2-degrees scenario, specifically for low-carbon technologies such as wind and solar technology. The overall increase in capacity naturally implies an increase in the stocks of three bulk materials, namely aluminum, steel and cement. In 2070, the 2-degrees scenario has 60 % more electricity generation capacity than the No Policy scenario (25 TW in No Policy, 40 TW in 2-degrees). Accordingly, the total material needs of electricity generation technologies in the 2-degrees scenario is 2.2 times higher than in the No Policy scenario (3049 Mt in No Policy, 6800 Mt in 2-degrees). The stocks of all three materials increase by similar amounts between the No Policy and 2-degrees scenario.