the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

PyCHAM (v2.1.1): a Python box model for simulating aerosol chambers

Simon Patrick O'Meara

Shuxuan Xu

David Topping

M. Rami Alfarra

Gerard Capes

Douglas Lowe

Yunqi Shao

Gordon McFiggans

In this paper the CHemistry with Aerosol Microphysics in Python (PyCHAM) box model software for aerosol chambers is described and assessed against benchmark simulations for accuracy. The model solves the coupled system of ordinary differential equations for gas-phase chemistry, gas–particle partitioning and gas–wall partitioning. Additionally, it can solve for coagulation, nucleation and particle loss to walls. PyCHAM is open-source, whilst the graphical user interface, modular structure, manual, example plotting scripts, and suite of tests for troubleshooting and tracking the effect of modifications to individual modules have been designed for optimal usability. In this paper, the modelled processes are individually assessed against benchmark simulations, and key parameters are described. Examples of output when processes are coupled are also provided. Sensitivity of individual processes to relevant parameters is illustrated along with convergence of model output with increasing temporal resolution and number of size bins. The latter sensitivity analysis informs our recommendations for model setup. Where appropriate, parameterisations for specific processes have been chosen for their general applicability, with their rationale detailed here. It is intended for PyCHAM to aid the design and analysis of aerosol chamber experiments, with comparison of simulations against observations allowing improvement of process understanding that can be transferred to ambient atmosphere simulations.

- Article

(899 KB) - Full-text XML

- BibTeX

- EndNote

Many major advances in atmospheric modelling have arisen from chamber observations: for example, the partitioning of vapours to particles (Odum et al., 1996), the gas-phase chemistry of ozone as part of the Master Chemical Mechanism (MCM) (Jenkin et al., 1997), and the gas-phase chemistries of limonene (Carslaw et al., 2012) and β-caryophyllene (Jenkin et al., 2012). Such advances can be incorporated into improved chamber models (e.g. Charan et al., 2019), aiding the design of experiments to interrogate further processes and systems (e.g. Peräkylä et al., 2020). As chamber use has multiplied, so too have chamber models, with many now published (Naumann, 2003; Pierce et al., 2008; Lowe et al., 2009; Roldin et al., 2014; Sunol et al., 2018; Topping et al., 2018; Charan et al., 2019; Roldin et al., 2019). Chamber scientists without modelling expertise or access may be limited in the design, interpretation and advancement of both chamber experiments and their contribution to models. To address this requirement PyCHAM (CHemistry with Aerosol Microphysics in Python) has been developed in the framework of the EUROCHAMP2020 Simulation Chamber Research Infrastructure (Oliveri, 2018).

In this paper the processes represented in PyCHAM are described, along with details of software application. Where relevant, equations are presented and output from PyCHAM is compared against benchmark simulations to assess accuracy and determine whether calculations are performing as intended. It is not the intention of this paper to compare PyCHAM against observations, which is the focus of future work. In the following two sections the objectives, rationale and structure of the software are explained.

Consistent with the criteria set by the EUROCHAMP2020 research project (Oliveri, 2018), PyCHAM is open-source (available at https://github.com/simonom/PyCHAM, last access: 27 January 2021), user-friendly and aims to be capable of representing the latest scientific understanding. It has been designed and tested on desktop computers for Windows, Linux and Mac operating systems. Python is the chosen language for two key reasons: code can be transferred between computers without the limitation of requiring a native or proprietary compiler (thereby improving ease of use and portability), and the relatively versatile parsing capability allows the user to readily vary model inputs. The accessibility, usability and basic functionality of PyCHAM have been reviewed in O'Meara et al. (2020). The current paper presents a detailed description and introductory analysis of the PyCHAM functionality that was not the focus of O'Meara et al. (2020).

Aerosol chambers (interchangeably called smog chambers), defined as those used for interrogating gas- and particle-phase processes, provide a method for isolating specific processes of interest without the conflating effects present in the ambient atmosphere. Ultimately, the goal of the chamber is to improve understanding and quantitative constraints on the evolution of the physicochemical properties of the gas and particle phase (Schwantes et al., 2017; Charan et al., 2019; Hidy, 2019). A description of chamber processes first requires consideration of the chamber characteristics, including wall material (frequently fluorinated ethylene–propene film – FEP Teflon – though others are used), lighting and dimensions. Two approaches are used to inlet components: batch mode, whereby set volumes of gas or particles are injected at specific times, or flow mode with a constant influx of gas or particles (Jaoui et al., 2014). The input file containing model variables for PyCHAM allows users to set up simulations for both modes along with other experiment descriptors that allow simulation of a broad range of chamber investigations: with or without seed particles; with or without nucleation; variable temperature, pressure and relative humidity; for illuminated experiments, either natural light intensity (for open-roof chambers) or known actinic flux (for chambers with bulbs) that can be turned on and off at set times. The full introduction to model variables is given in Sect. 4.

Two previous models act as platforms on which was PyCHAM developed: the Microphysical Aerosol Numerical model Incorporating Chemistry (MANIC) (Lowe et al., 2009) and PyBox (Topping et al., 2018), with the former guiding multi-phase processes and the latter guiding Python parsing and automatic generation of chemical reaction modules. PyCHAM treats gas-phase photochemistry, gas–particle and gas–wall partitioning, coagulation, nucleation, and particle deposition to walls in zero dimensions. A key feature is its aim to be generally applicable such that gas–wall partitioning, particle deposition to walls and nucleation – all processes with outstanding uncertainties – are parameterised and may be fitted to observations. Below we detail the constraint necessary for fitting the relevant parameters. The full list of PyCHAM applications is numerous and will increase as chamber experiments evolve. Key applications include designing chamber experiments, developing gas-phase photochemistry mechanisms, quantifying gas–wall partitioning parameters, developing nucleation models and interrogating the effects of processes on secondary particulate matter (SPM) evolution.

The processes included in PyCHAM are typically a subset of those represented in large-scale (regional and global) atmospheric models, and it is intended that once a process has been successfully modelled by PyCHAM it can be transferred, possibly via parameterisation, to a large-scale model for evaluation and application (as illustrated by the gas–particle partitioning and gas-phase chemistry advances cited in the Introduction). When interrogating the simulation of a given process it is necessary that conflating processes are modelled accurately such that uncertainty around their effects is not compromising. Therefore, the main objective of this paper is to assess the accuracy and precision of the fundamental representation of the individual processes considered in PyCHAM through comparison with benchmark simulations. Comparison of some results presented below with experimental observations is possible; however, it is beyond the scope of this paper to investigate the accuracy of chemical mechanisms or estimation methods that PyCHAM can use. Rather, the examples below illustrate the utility of PyCHAM to test the sensitivity of such techniques.

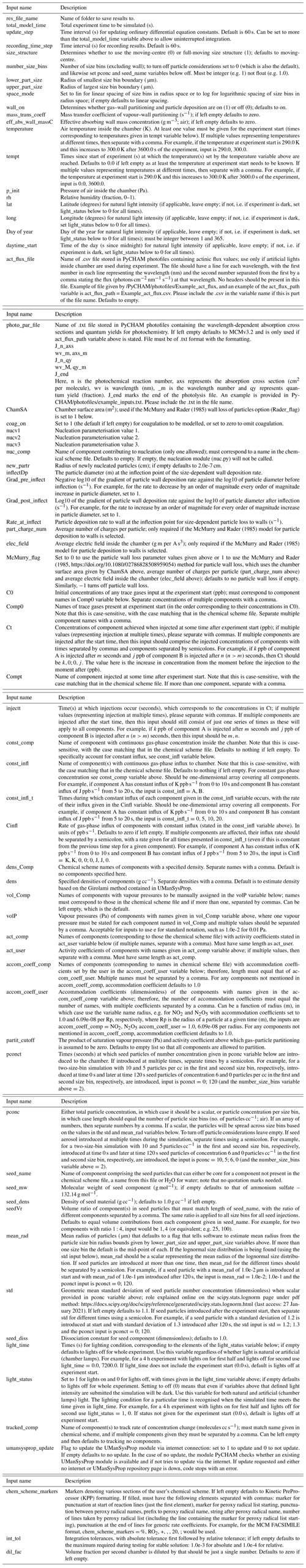

An example of PyCHAM application in which several major processes are influential is provided by simulating an experiment based on the role of the nitrate radical (NO3) oxidation of limonene in secondary organic particulate matter (SOPM) evolution (Fig. 1). Such an experiment has implications for indoor air quality at night-time when the photolysis of NO3 ceases (Waring and Wells, 2015); therefore, lights were turned off for this simulation. Following a similar approach as in the experiment of Fry et al. (2011), the effect of NO3 in the presence of ozone (O3) is replicated by first injecting nitrogen dioxide (NO2), limonene and carbon monoxide into the chamber, with the latter removing the effect of the hydroxyl radical – this initial injection of components marks the start of the experiment. After 1.5 h O3 is injected to initiate oxidation, and in the absence of seed particles Fry et al. (2011) show that this mixture initiates a nucleation event, which we simulate here through the nucleation parameterisation described below. Another injection of O3, NO2 and limonene at 4 h with the addition of seed aerosol simulates indoor environments with substantial existing particulate matter.

In Fig. 1 the particle organic nitrate curve demonstrates that around 15 % of SOPM comprises organonitrates that result from NO3 reaction. Relative humidity was set to 50 %, and water partitioning with particles is modelled using the gas–particle partitioning calculations described below. The particle inorganic nitrate curve represents the contribution of dinitrogen pentoxide (N2O5) to the particle phase in PyCHAM. Gas–particle partitioning of N2O5 is driven by nearly instantaneous hydrolysis to nitrate ions on contact with the aqueous phase of particles, which maintains a zero particle-phase mole fraction of N2O5. Thus, mass transfer of N2O5 to the particle continues according to the Raoult's law partitioning theory that we detail in Sect. 6. Here we simulate the instantaneous hydrolysis of N2O5 to nitrate ions by setting the activity coefficient to zero and estimating the accommodation coefficient according to Lowe et al. (2015), which estimates the rate of condensation as dependent on the Henry's law constant and diffusion constant of N2O5 in the aqueous phase. Assuming homogenous particles for a given size bin (j), Eq. (7) of Lowe et al. (2015) is

where t represents time, R is the universal gas constant, T is temperature (set to 298 K), c is average velocity in the gas phase and r is particle radius. HaqDaq is the product of the Henry's law constant and diffusion constant in the aqueous phase for N2O5, with the former set to 5×103 M atm−1 and the latter to 1×109 m2 s−1 (Lowe et al., 2015).

Figure 1Limonene oxidation in the dark with and without seed particles. In (a) are the gas-phase concentrations of key components, and in (b) are the particle properties. At the start 10 ppb of limonene, 22 ppb of NO2 and 500 ppm of CO are introduced. At 1.5 h 38 ppb of O3 and 8 ppb of NO2 are injected (injection 1). At 4 h a further injection of O3 (45 ppb), limonene (10 ppb) and NO2 (19 ppb) is coincident with an injection of seed aerosol (10 µg m−3 with a mean diameter of 0.2 µm) (injection 2). In (b), the total particle number concentration (N) corresponds to the first of the right axes. The second of the right axes corresponds to the following: the mass concentration of secondary organic particulate matter (SOPM), components deposited to walls (wall deposit), the sum of particulate organic components with a nitrate functional group (particle organic nitrate) and the sum of particulate inorganic components with a nitrate functional group (particle inorganic nitrate). Number size concentrations correspond to the filled contours, colour bar and left axis. Whilst N includes seed particles, SOPM excludes the seed material, and all mass concentrations exclude water.

A current limitation of PyCHAM is its lack of explicit treatment of particle-phase processes including reaction and dissolution. Furthermore, there is currently no thermodynamic module to estimate divergences from ideality. As a result of these two limits, particle-phase processes can currently only be reproduced through manual setting of individual component activity coefficients, accommodation coefficients and vapour pressures. For the example in Fig. 1, N2O5 is the only component to be treated non-ideally by setting of its activity coefficient to zero to simulate nearly instantaneous hydrolysis to nitrate ions.

Studies have recently revealed the role of highly oxidised molecules (HOMs) (Ehn et al., 2014), with the peroxy radical autoxidation mechanism (PRAM) simulating their chemistry (Roldin et al., 2019). For the results in Fig. 1, the PRAM scheme has been coupled with that of the Master Chemical Mechanism (MCM) (Jenkin et al., 1997; Saunders et al., 2003). It is intended that simulations such as that in Fig. 1 can help constrain uncertainties in new chemical schemes through comparison with observed particulate loading and composition analysis.

The primary difference between multi-phase processes in simulation chambers and the real atmosphere is the presence of walls. Accurate representation of these processes in chamber models requires a reasonable and realistic representation of the chamber walls (e.g. Matsunaga and Ziemann, 2010; Zhang et al., 2015). Clearly, PyCHAM must reasonably capture the partitioning of components and deposition of particles to chamber walls as incorrect reproduction makes comparison against measurements misleading or impossible. However, with a correct wall loss constraint, simulations such that in as Fig. 1 can be compared against observations to verify process understanding.

For ease of navigation, PyCHAM has a modular structure with each key physicochemical process assigned an individual module. Unit tests are provided for modules, allowing the user to check whether a particular process is functioning correctly. It is intended that these tests will be useful for troubleshooting and for analysing the effects of modifications to modules.

At the core of PyCHAM lies simultaneous numerical integration of three coupled processes: gas-phase photochemistry, gas–particle partitioning and gas–wall partitioning. The units for the rate of change for all processes is , and the Jacobian matrix is specified at each integration step. The ordinary differential equations (ODEs) for these processes are solved by the backward differentiation formula, the utility of which has been demonstrated in similar atmospheric applications (Jacobson, 2005), from the SciPy package for scientific computing in Python.

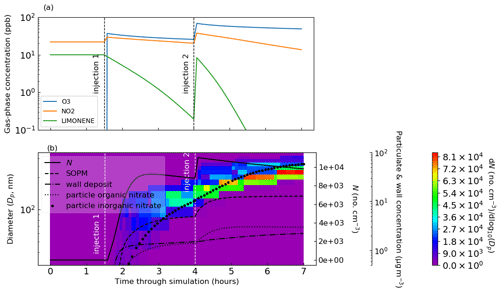

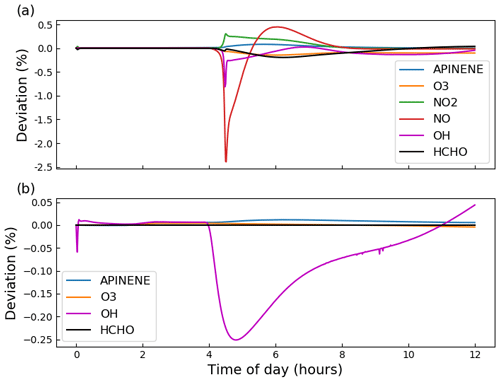

The model structure is outlined in the schematic in Fig. 2, where we introduce the “update time interval”, which is an important input set by the user. This interval determines the frequency at which the natural light flux is updated since it will change during the course of an open-roof experiment (in contrast to chamber lamps that have a constant actinic flux). The update time interval also sets the frequency at which the particle number concentration is affected by coagulation, particle deposition to walls and nucleation (important for simulations involving particles). Particle number concentration and photolysis rates are constants in the ODEs for gas–particle partitioning and gas-phase photochemistry, respectively. The update time interval is passed to the integrator, which adaptively sets sub-time steps depending on problem stiffness. As such, a simulation without varying natural light and without particles could have an update time interval equal to the total experiment time without any loss of detail. For discontinuous changes to chamber conditions, such as turning lamps on–off and the injection of gas-phase components or seed particles, automatic adaption of the update time interval ensures occurrence at the start of an integration step.

Figure 2Schematic outlining the PyCHAM structure. In the left column are the GUI buttons that initiate the action(s) in the central column. On pressing the “run model” button PyCHAM loops over the “update time interval” until the experiment end time is reached. On each loop PyCHAM first checks whether any discontinuous changes to the chamber condition occur during the proposed time interval and automatically reduces the interval if confirmed such that the change can be implemented at the correct time at the start of the subsequent interval. Depending on problem stiffness the integrator uses sub-time steps, with the model taking the result at the end of the integration period. The final stage of a loop wherein the update time interval has been reached is the solution of coagulation, particle deposition to walls and nucleation, which update the particle number concentration. The right column notes these temporal resolution aspects, with the mentioned sensitivity of key system properties investigated in Sect. 11.

Whilst coagulation and particle loss to walls have timescales of minutes to hours, nucleation can cause substantial changes within seconds (Sect. 11). Users may increase the update time interval, which has the advantage of decreased processing time, defined here as the time taken by a computer to complete all core PyCHAM commands, and the disadvantage of divergence from high-resolution estimates. Simulation sensitivity to temporal resolution is investigated in Sect. 11, including recommendations for maximum time intervals.

In the example model output in Fig. 1, several features of PyCHAM are demonstrated. The first is the coupling of gas-phase chemistry and resulting partitioning of vapours with sufficiently low volatility to particles and walls. Nucleation was simulated prior to the introduction of seed particles, with values provided for the nucleation parameters (Sect. 10) to ensure that nucleation begins at the introduction of ozone, has a duration of 30 min and produces a peak number concentration similar to that of the seed particle. Finally, coagulation and particle wall loss (the latter using the model of McMurry and Rader, 1985) contribute to the decay in particle number concentration.

The PyCHAM software is initiated via the command line to generate a graphical user interface (GUI). Via the GUI, users select three files (Fig. 2) representing (i) the chemical scheme, (ii) a file associating the chemical identifiers inside the chemical scheme with their simplified molecular input line-entry system (SMILES) strings (Weininger, 1988) and (iii) a file containing model variables. A fourth button on the GUI starts the simulation.

A parsing module interprets the chemical scheme and uses the chemical identifier conversion file to match component identifiers to their SMILES strings. For the chemical scheme file delimiting markers are required at certain points; however, the form of these markers and the structure of the chemical scheme file may vary so long as the markers are specified by the user in the file containing model variables before running the programme. Consequently, a chemical scheme file downloaded directly from the MCM website may be used without modification in combination with a relevant file containing model variables.

On running PyCHAM, modules are automatically created that will track chemical tendencies (rate of change due to individual chemical reactions) and process tendencies (rate of change due to gas–particle and gas–wall partitioning) of specified components. A gas-phase initiation module interprets the user-defined starting concentrations of components, whilst a particle-phase initiation module establishes any seed particles at the experiment start. The integration module is then called, whereby the ODEs for gas-phase photochemistry and partitioning are solved (Fig. 2). A saving module stores results by default for gas and wall concentrations of all components, corresponding time, and constants such as component molecular weight. If the user has set up the simulation to include particles, then the particulate concentration for all components and particle number size distributions (with and without water) are also saved. If the user has defined components to track, then the change tendencies of these are saved, including rates of change due to photochemistry and partitioning to particles and walls.

The fifth button on the GUI will display and save graphs of the temporal profiles of number size distribution, secondary aerosol mass concentration, total particle number concentration and the gas-phase concentrations of the components whose initial concentrations are user-defined. Besides these default plots, utility is enhanced through additional examples of plotting scripts (those used for figures here) in the PyCHAM repository. Furthermore, the script vol_contr_analys provides an example of how to generate a comma-separated value (csv) file containing the names of components, their saturation vapour pressures at 298.15 K and particle-phase mass concentrations as a function of time. This script can also plot a volatility basis set analysis of particle-phase mass fraction with time. The programme can be stopped via the terminal when in integration mode, or outside this mode it can be terminated by closing the GUI.

Below we describe and verify the processes described above as coded in PyCHAM. Necessarily each process is examined in isolation; however, Fig. 1 and its associated text illustrate the coupling of mechanisms for a real-world application.

As described above, to initiate PyCHAM the user selects a completed model variables input file (an example is provided with the software). The available variables are extensive to allow adaptability to a range of experiments; consequently, for a given experiment, many of the variables in this file may be left empty. Here we introduce the available variables, whilst details such as default values and units are provided in the Appendix Table A1. Several model variables (PyCHAM names of variables given in brackets) are purely functional; these include the name of the output file (res_file_name), whether to update the component property estimation files (umansysprop_update), which are described below in this section, the markers used to separate sections of the chemical scheme (chem_scheme_markers), names of files containing actinic flux (act_flux_file) and absorption cross sections, and quantum yields for photochemistry (photo_par_file). Total simulation time (total_model_time), the time interval for updating integration constants (update_step) and the time interval for recording results (recording_time_step) are also available.

Chamber temperature (temperature) can change during a simulation by stating the corresponding time (tempt), whilst pressure (p_init) and relative humidity (rh) are also input. All relevant thermodynamic properties change accordingly with temperature, such as component vapour pressures and gas-phase diffusivities.

For simulations involving natural light, latitude (lat), longitude (long), day of year (day of year) and start time (daytime_start) are required inputs. Whether artificial or natural, users specify when (light_time) light is on or off (light_status). Any dilution rate (dil_fac) should be stated, or else the default is zero.

Initial concentrations (C0) of specified trace gases (Comp0) are stated separately to the concentrations (Ct) of specified trace gases (Compt) injected effectively instantaneously at set times (injectt) during the experiment. Specified components (const_comp) will have a constant concentration for the entire experiment. The final option for introducing named components (const_infl) is to state the rate of their influx (Cinfl) during a set period of the experiment (const_infl_t). The change tendencies (defined above) of certain components (tracked_comp) can be recorded, which is helpful for analysis and troubleshooting.

For specific components (vol_Comp), liquid-phase saturation vapour pressures can be manually assigned (volP), as can activity coefficients (act_user) and accommodation coefficients (accom_coeff_user).

To simulate gas–wall partitioning, the mass transfer coefficient (mass_trans_coeff) and effective absorbing wall mass concentrations (eff_abs_wall_massC) can be set.

For the particle phase, users state the number of size bins (number_size_bins), the size at the lowermost size bin boundary (lower_part_size) and at the uppermost boundary (upper_part_size), and whether to have linear or logarithmic spacing of size bins (space_mode). Setting the size bin number to zero turns off particle considerations. As detailed below, users can also specify whether to use the moving-centre or full-moving size structures for dealing with changing particle number size distributions (size_structure).

For seeded experiments, the component comprising the seed (seed_name), its molecular weight (seed_mw), density (seed_dens) and dissociation constant (core_diss) can be input. Either the particle concentration per size bin or the total particle concentration can be input (pconc), along with the time of particle injection (pconct). If the total particle concentration is given, this can be distributed across size bins by stating the mean radius (mean_rad) and standard deviation (denoted in PyCHAM as std).

For nucleation experiments, the nucleating component (nuc_comp) can be changed from the default, as can the radius of newly nucleated particles (new_partr). To specify the temporal profile of nucleation, three parameters (detailed in Section 10) are input (nucv1, nucv2, nucv3).

Coagulation (coag_on) and particle loss to walls (McMurry_flag) can be turned off and on. If the latter is turned on, users can specify the size-dependent loss to walls (inflectDp, Grad_pre_inflect, Grad_post_inflect and Rate_at_inflect) or invoke the McMurry and Rader (1985) model by also inputting the chamber wall surface area (Cham_SA), the charge per particle (part_charge_num) and the chamber electric field (elec_field), which are detailed in Sect. 9.

The components included in the user-defined chemical scheme are automatically allocated three properties by the PyCHAM software: molecular weight, pure component liquid density and pure component liquid saturation vapour pressure. Molecular weights are estimated by passing SMILES strings to the PyBEL module of the Open Babel chemical toolbox (O'Boyle et al., 2011). Open Babel is installed as part of the PyCHAM package and generates unique chemical identifiers for each component based on their SMILES string. For estimating component densities and liquid-phase saturation vapour pressures, the PyBEL chemical identifiers are passed to the UManSysProp module (Topping et al., 2016), which is updated on the first run of PyCHAM and at the request of the user (via the file containing model variables) thereafter (requires internet connection). By default the UManSysProp module applies the liquid density estimation method of Girolami (1994) (recommended by Barley et al., 2013) and the liquid saturation vapour pressure estimation method of Nannoolal et al. (2008) (recommended by O'Meara et al., 2014). Component vapour pressures have a first-order effect on absorptive partitioning between phases; however, estimates for components with relatively low vapour pressures (below 1 Pa at 298.15 K) are associated with considerable uncertainty (O'Meara et al., 2014), as these are most difficult to measure experimentally and therefore inform estimation methods. Consequently, users can also specify the vapour pressures of certain components. Similarly, although the default activity and accommodation coefficient for all components partitioning to particles and walls are unity, users may set an alternative value for specific components. At present, activity coefficient calculations are not incorporated into PyCHAM.

For a chamber experiment including injection of reactive components, chemical reactions in the gas phase drive the disequilibria that can affect the composition of gas, particles and walls. As mentioned above, schemes such as the MCM provide nearly explicit gas-phase chemistry mechanisms for numerous organic precursors, and developments such as PRAM (Roldin et al., 2019) can be used to provide supplementary detailed updates to our understanding of atmospheric chemistry. PyCHAM is designed to accommodate any such detailed chemical schemes whilst also accepting very simplified or even empty (e.g. for a control simulation comprising only seed particles) chemical equation files. Whilst the software manual details the requirements for input chemical schemes and chemical identifier conversion files, here we describe how PyCHAM deals with chemistry. Equations of the general form

where s represents stoichiometric number, r reactants and p products, are expressed as the ODEs:

where n is the total number of reactants and rj is a given reactant for a given reaction. kr is the reaction rate coefficient.

For simulations involving gas-phase chemistry, users must provide a reaction of the form in Reaction (R1) and an associated reaction rate coefficient inside a chemical scheme file. Naming of chemical components inside the chemical scheme is unrestricted; however, the software must be able to convert names to SMILES (Weininger, 1988). Therefore, users must provide a separate file stating a unique SMILES string for every component (Fig. 2). Examples of both the chemical scheme and SMILES string conversion file are included in the software.

Inside the parsing module, reaction rate coefficients, reactant and product identities, and their stoichiometric numbers are established from the chemical scheme file. To separate these properties either default formatting or a variant may be used, so long as the appropriate changes are made inside the file containing model variables. By default, MCM Kinetic PreProcessor (Sander and Sandu, 2006) formatting is used (Jenkin et al., 1997; Saunders et al., 2003), and PyCHAM has been rigorously tested using schemes and SMILES conversion files from the MCM website (Rickard and Young, 2020).

Reaction rate coefficients can be functions of temperature, relative humidity, pressure and concentrations of third body, nitrogen, oxygen and peroxy radicals. Third body, nitrogen and oxygen concentrations are calculated by the ideal gas law with the user-set temperature and pressure. As in the MCM, the chemical scheme file can include generic reaction rate coefficients (those that have an identifier which is used as the reaction rate coefficient for one or more reactions).

Photochemistry is controlled through stating light on–off times inside the file containing model variables. The treatment of photochemistry is determined by the user and depends on the chemical scheme employed. In the case of the MCM scheme and natural sunlight, the scattering model based on Hayman (1997) and described in Saunders et al. (2003) is invoked by stating the relevant spatial and temporal coordinates in the file containing model variables. For artificial lights, users must provide a file stating the wavelength-dependent actinic flux (as described in the manual). The model then calls on either the absorption cross section and quantum yield estimates of MCM v3.3.1 or of a user-defined file.

5.1 Assessment of gas-phase photochemistry accuracy

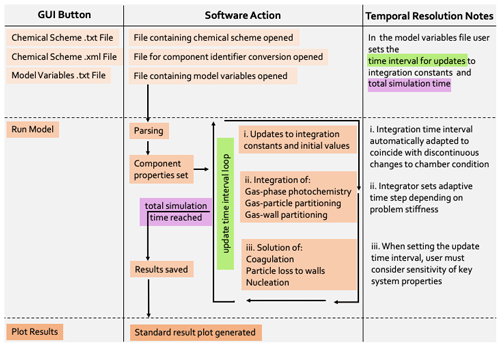

To assess the accuracy of the photochemistry section of PyCHAM, gas–particle partitioning and gas–wall partitioning were turned off, leaving only gas-phase chemistry to be solved. Here we compare against AtChem2 (Sommariva et al., 2020) as a model benchmark, with both using MCM chemical schemes. Figure 3 shows the deviation with experiment time for two standard aerosol chamber characterisation experiments: α-pinene ozonolysis in the presence (panel a) and absence (panel b) of NOx. To test both dark and illuminated scenarios, the simulation is for an aerosol chamber with an open roof, starting at midnight and finishing at midday. Initial concentrations of α-pinene and O3 were equal at 21.1 ppb for both experiments, whilst for NOx the initial concentration was 9.8 ppb in Fig. 3a and 0 ppb in Fig. 3b. Latitude was set to 51.51, longitude to 0.13 (London, UK) and the date to 1 July. In both models, absolute error tolerance was set to and relative tolerance was set to . AtChem2 has no functionality for gas–particle partitioning, which is fine for this section dealing with only gas-phase photochemistry, whilst PyCHAM had particle considerations turned off. The deviation between PyCHAM and AtChem2 was calculated using

where σi,t is the percentage deviation (%) for component i at time t, s is the PyCHAM result and b is the AtChem2 result. ∨(bi) is the AtChem2 maximum for a given component during the simulation, which is the chosen scaling factor for deviations as it means any difference between model estimates is referenced against a reasonable value for that component (in contrast, scaling by bi,t when may introduce a very large percentage deviation for a relatively very small difference between model estimates).

Figure 3Gas-phase photochemistry verified; simulations of photochemistry in an aerosol chamber exposed to natural light, for which deviation is defined in Eq. (4). α-Pinene ozonolysis is simulated in both plots, with α-pinene and O3 given the same initial concentrations of 21.1 ppb; initial NOx concentrations of (a) 9.8 ppb and (b) 0 ppb. For both simulations, the aerosol chamber is transparent and exposed to daylight without cloud interference, with dawn at approximately 4 h. Gas–wall partitioning is turned off in PyCHAM to be consistent with the AtChem2 model, and no particles are present in either model.

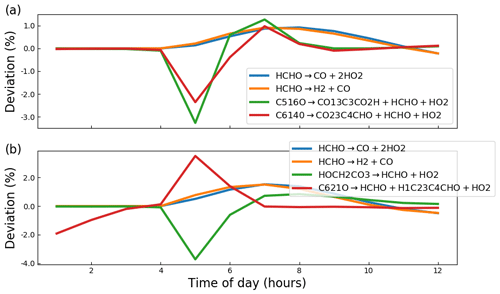

Whilst Fig. 3 indicates that PyCHAM performs well for components with both relatively short (e.g. OH) and long (e.g. α-pinene) lifetimes, it is necessary to ascertain that agreement is gained through the correct mechanism. The chemical change tendencies of formaldehyde were tracked in both PyCHAM and AtChem2 for the α-pinene ozonolysis simulations used for Fig. 3. Deviations of PyCHAM results from AtChem2 were calculated using Eq. (4), but with concentrations replaced by change tendencies resulting from individual reaction channels. Of the loss and production channels for formaldehyde the two of each with the greatest deviation are shown in Fig. 4. The low deviation values in Fig. 4 demonstrate that PyCHAM indeed solves gas-phase photochemistry correctly.

Figure 4Deviation of PyCHAM change tendency (rate of change due to individual chemical reactions) for formaldehyde (HCHO) from AtChem2 simulations for the MCM reactions given in the legends (the loss and production channels of formaldehyde with the greatest deviation). The definition for deviation is given by Eq. (4). Both plots are results for the α-pinene ozonolysis reaction described in the main text for Fig. 3 (a) in the presence of NOx and (b) in the absence of NOx.

5.2 PyCHAM sensitivity to temporal resolution of continuous photolysis change

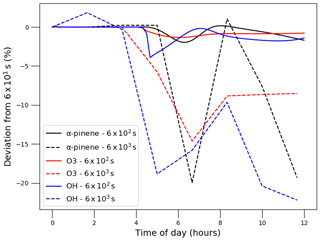

To minimise processing time, users can increase the update time interval (Fig. 2); however, this decreases the frequency of update for natural light intensity (note that for artificial light simulations, PyCHAM automatically adapts the time interval to coincide with timings of lights being turned on or off). For open-roof experiments, increasing the update time interval therefore reduces the accuracy of estimated photolysis rates. To illustrate and quantify the issue, the same scenario described above for Fig. 3 is used, i.e. a gas-phase-chemistry-only simulation with increasing natural sunlight intensity. Now we compare PyCHAM low temporal resolution (update time intervals of 6×102 and 6×103 s) with PyCHAM high resolution (updates every 6×101 s). To quantify divergence of low-resolution results from high-resolution results we use Eq. (4). Figure 5 shows the loss of accuracy rising to 20 % for the lowest-resolution case for both short- and long-lived components. Processing time for the 6×103 s resolution was 4 s using a 2.5 GHz Intel Core i5 processor; this increased by a factor of 4 for the 6×102 s resolution and by 23 for the 6×101 s resolution. Users should conduct a similar test for whether their chemical schemes or environmental conditions vary significantly from those here.

Figure 5Illustrating the effect of update time interval resolution in PyCHAM on gas-phase concentrations of α-pinene, O3 and OH for the experiment described above in Fig. 3 with α-pinene ozonolysis in the presence of NOx. Time intervals were set to 6×102 and 6×103 s as shown in the legend, and the deviation is from results for a time interval of 6×101 s.

PyCHAM simulations, like chamber experiments, are possible with and without seed particles. For seed particles, the user defines the number size distribution and composition inside the input file containing model variables. Furthermore, because PyCHAM uses size bins to discretise particles, users can state the number of size bins, lower and upper bin bounds, and whether to use linear or logarithmic spacing of size bins.

Particle number size distribution can change as a direct consequence of four processes modelled by PyCHAM: gas–particle partitioning, coagulation, nucleation and particle loss to walls. Whilst coagulation, nucleation and particle wall loss are discussed below, gas–particle partitioning is solved with (Zaveri et al., 2008)

where component i partitions to a size bin j from the gas g, with N size bins present. x is the particle-phase mole fraction, p0 is the pure component liquid (sub-cooled if necessary) vapour pressure, Kv is the Kelvin factor and γ is the activity coefficient. ki,j is the first-order mass transfer coefficient for component i to size bin j, which includes the transition regime correction factor of Fuchs and Sutugin (1971). As suggested by Eq. (5) all components are allowed to partition between the gas and particle phase, with the concentrations of individual components in each size bin of the particle phase tracked in addition to their gas-phase concentrations (both in units of molecules cm−3). The unit test test_partit_var is available to check that the Kelvin and Raoult effects of the PyCHAM gas–particle partitioning equation are accurate (e.g. through comparison with Fig. 16.1 of Jacobson, 2005). By default PyCHAM assumes an ideal system with no particle-phase mass transfer limitation to partitioning. However, users can diverge from ideality by setting γ, and they may replicate changes in particle viscosity via the accommodation coefficient, which is used to estimate ki,j.

In this section we focus on how PyCHAM treats changing particle number size distribution due predominantly to gas–particle partitioning. PyCHAM provides the option of using either the moving-centre or full-moving size structure (Jacobson, 2005) for evolving size distributions. The moving-centre approach has the advantage of minimal numerical diffusion, and it readily accommodates populations of particles of varying modes (e.g. a nucleation event in the presence of pre-existing particles). However, it suffers from loss of accuracy due to averaging of particles originally from different size bins that have grown, shrunk or coagulated to a given size bin (Zhang et al., 1999). In contrast, the full-moving structure does not average particles of different size bins together following gas–particle partitioning and can therefore exactly model certain chamber scenarios. The full-moving structure less readily accommodates multiple populations of particles, such as the nucleation event followed by seed particle injection used in Fig. 1. Therefore, in the interest of generality the default size structure in PyCHAM is moving-centre, and unless otherwise stated all results in this paper use it.

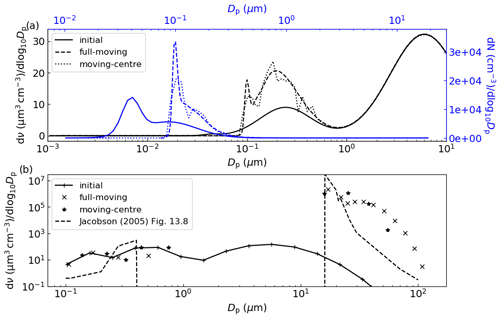

Here we assess the moving-centre and full-moving size structures through analysis of output during two periods of relatively substantial (and therefore testing) condensational growth and compare to benchmark simulations. The simulations also illustrate two further means of component influx to chambers using PyCHAM in addition to the simulations above in which components were introduced with an initial pulse. In the first case a constant flux of sulfuric acid is added to a chamber with seed aerosol typical of hazy conditions following the benchmark simulation of Zhang et al. (1999). For consistency with the benchmark, gas and particle partitioning to walls was turned off and sulfuric acid was assumed to be non-volatile. The analysis section of Zhang et al. (1999) notes that to resolve the growth of the smallest particles in this scenario, the spatial resolution must be at least 100 size bins; therefore, we use this value and set the update time interval to 90 s for a total 12 h simulation.

The exact solution to this condensational growth problem is given by the full-moving output in Fig. 6a, which replicates that in Fig. 3 of Zhang et al. (1999). Comparing the moving-centre output against the full-moving output we see that the tri-modal distribution is present, with mean values at the correct particle size though with lower peak height and greater spread (for both volume and number size distributions), indicating numerical diffusion. The degree of agreement is significantly better than for the 13-size-bin moving-centre simulation presented in Zhang et al. (1999) and indicates that PyCHAM is operating as intended. Our results in Fig. 6a are a two-point moving average, which is often necessary for the moving-centre structure because of its requirement that all particles in a size bin be transferred to the adjacent bin, meaning that some bins will intermittently have zero particles.

Figure 6In (a) is a replication of Fig. 3 of Zhang et al. (1999), where constant influx of sulfuric acid condenses to seed particles with the shown initial volume size distribution (bottom and left axis, in black) and initial number size distribution (top and right axis, in blue), with final results after 12 h. In (b) is a replication of Fig. 13.8 of Jacobson (2005), where an initial distribution of particles is subject to a relative humidity of 100.002 % at minute intervals for 9 min, with results shown after 10 min.

Another case of relatively intense vapour–particle partitioning is provided by the example of cloud condensation nuclei experiencing varying degrees of water vapour supersaturation. Chamber experiments may involve injections of a component at specific times, and the input file containing model variables can accommodate such a scenario. Making use of this function we reproduce the benchmark simulation of Jacobson (2005) (Fig. 13.8) wherein relative humidity is increased to 100.002 % every minute (including at simulation start) for 9 min, with results analysed after 10 min. Seed particles are assumed to be non-volatile and wall interactions are turned off. The parameters temperature, seed component dissociation constant, molecular weight and density are not disclosed by the reference simulation; therefore, we set these as 300 K, 1, 350 g mol−1 and 0.9 g cm−3, respectively. The comparison between the Jacobson (2005) result in Fig. 6b and PyCHAM outputs certainly shows agreement in the main feature of this simulation, which is the initially larger particles out competing smaller particles for water condensation to grow to water droplet size (Dp>10 µm). It should be noted that this is a much more stringent test of the representation of partitioning than is ever intended for PyCHAM, which will not generally be used for the huge mass flux of condensing material experienced under water-supersaturated conditions. Nevertheless, the PyCHAM result gives reasonable agreement considering that key parameters (such as seed component dissociation) may vary between simulations, and taken together with Fig. 6a this verifies the operation of gas–particle partitioning and both the moving-centre and full-moving size structure.

The partitioning of gases to the chamber wall is often termed wall loss, as the net movement is from the gas phase to the wall (for an initially clean chamber wall). Traditionally this process has been viewed as an inconvenience since chamber results often depend on the concentration of gas and particle phases of certain components, whilst the fraction of these components lost to walls is poorly constrained. Several studies have focussed on partitioning to Teflon walls, which are frequently employed (Matsunaga and Ziemann, 2010; Zhang et al., 2015; Zhao et al., 2018); however, the process remains poorly modelled across the wide range of chamber materials, relative humidities, gas-phase loading, component volatilities and activity coefficients present in chamber experiments (e.g. Bertrand et al., 2018).

A volatility-dependent gas–wall partitioning parameterisation for Teflon chambers has been suggested by Krechmer et al. (2016); however, they recommend further investigation into its suitability across chamber experiment conditions. Because this paper is focussed on describing PyCHAM in its most generally applicable form, we do not analyse specific models here; however, users are encouraged to adapt the programme based on their particular experiment conditions.

It is therefore preferable to allow the user to fit vapour losses to walls through the tuning of two wall loss parameters, one primarily determining equilibrium, called the effective wall mass concentration (Cw), and one determining the rate of partitioning, called the mass transfer coefficient (kw). These influence gas–wall partitioning through an equation of the same framework as gas–particle partitioning (which is described in Sect. 6 and in Zaveri et al., 2008):

where is the liquid (sub-cooled if necessary) saturation vapour pressure of component i and γi is its activity coefficient on the wall. Following the conclusions of Matsunaga and Ziemann (2010) and Zhang et al. (2015), kw represents factors such as gas- and wall-phase diffusion, turbulence, the accommodation coefficient, and the chamber surface area to volume ratio, whilst Cw reflects the adsorbing and/or absorbing properties of the wall, including effects of relative humidity, surface area, diffusivity and porosity. We recommend the iterative fitting of kw and Cw to observations through minimising observation–model residuals. Cw in PyCHAM does not vary with the mass transferred to the wall, which is consistent with the findings of Matsunaga and Ziemann (2010) and Zhang et al. (2015) that indicate the effective mass concentration of the wall is much larger than the mass concentration of transferred material.

7.1 Tuning gas–wall partitioning parameters

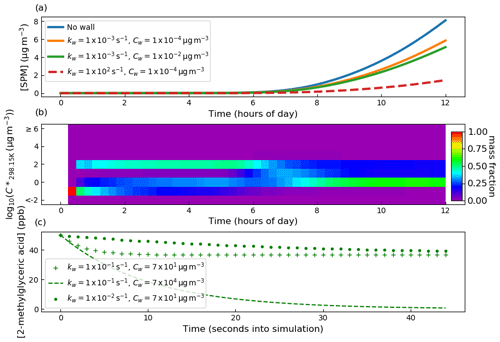

Next we illustrate the sensitivity to kw and Cw in Eq. (7). The same simulation setup described above for Fig. 3 was used though with α-pinene replaced by isoprene (using the chemical scheme of MCM v3.3.1) with a concentration at experiment start of 63.4 ppb. Seed particles comprised of ammonium sulfate with mean diameter µm and number concentration 1.5×104 cm−3 were introduced at the experiment start; this equates to a mass concentration of 8 µg m−3. Pure component liquid saturation vapour pressures were estimated by the Nannoolal et al. (2008) method, and activity coefficients for all components were assumed to be unity. In this example and throughout this paper, all components are allowed to partition between the gas and particle phase according to Eq. (5).

To begin, both kw and Cw were set sufficiently low to effectively eliminate gas–wall partitioning. Second, Cw was set to µg m−3 and kw set to s−1, at which a notable decrease in secondary particulate matter (SPM) was observed. Third, kw was held constant, whilst Cw was raised 2 orders of magnitude greater to µg m−3. Fourth, Cw was held constant at µg m−3, and kw was raised by 5 orders of magnitude to 1×102 s−1. The effect on secondary particulate matter mass concentration is given in Fig. 7 and demonstrates that at sufficiently large values of Cw and kw, SPM production can be effectively suppressed through competitive uptake of vapours to chamber walls. However, it should be noted that for a given Cw, there is a limit to suppression of SPM due to kw increase as it affects only the rate of partitioning with walls rather than the condensable fraction.

Figure 7In (a) is the sensitivity of SPM mass concentration to the gas–wall partitioning parameters kw and Cw from Eq. (7). Seed particles with a concentration of 8 µg m−3 were present at the start of the experiment. Initial concentrations of O3, isoprene and NO2 were set to 21.1, 63.4 and 9.8 ppb, respectively. With regards to photolysis rates, the simulation made the same considerations as in Fig. 3, where natural sunlight drove reactions after dawn at approximately 4 h. Panel (b) illustrates a PyCHAM plotting tool for contributions of components in volatility bands to secondary particulate matter as a function of time. The example given is for the no-wall case in (a). In (c), the sensitivity of the gas-phase concentration decay of 2-methylglyceric acid is shown for a control experiment in which only a single organic component is present in the absence of particles. Wall loss parameters are given in the legend.

Whilst the intention of this section is the demonstration of gas–wall partitioning, and it is beyond the scope of this paper to evaluate the chemical schemes or property estimation techniques that may be used by PyCHAM, comparison of Fig. 7a with observations is insightful. As discussed earlier, PyCHAM currently does not account for heterogenous or particle-phase reaction or oligomerisation. However, these processes are reported to have a significant impact on secondary particulate matter formation from isoprene (Sato et al., 2011; D'Ambro et al., 2017); therefore, we would expect a lower yield in Fig. 7a than reported from observational studies. Observations from a similar aerosol chamber experiment are presented in Table 1 (experiment number 10) of Liu et al. (2016). Consistent with our expectation, after wall loss correction they report a secondary organic aerosol yield of 11.6 %, whereas for Fig. 7a here the no-wall case gives a yield of 4.5 %. However, Sato et al. (2011) observed a yield of 5.5 % for isoprene photooxidation in the presence of 22 ppb of NOx and neutral seed particles. Given that Sato et al. (2011) also observed up to 1∕3 the organic particulate concentration comprising oligoesters that are not currently simulated in PyCHAM, the yield found here is relatively high. Whilst not in the scope of the current paper to pinpoint the cause of this discrepancy, it is worth noting that in Table 6 of O'Meara et al. (2014) the Nannoolal et al. (2008) estimation method for component vapour pressures generated between 2 to 3 times more secondary particulate matter mass concentration than when measured vapour pressures were used. This is due to the disproportionate effect on SPM from underestimating component vapour pressures compared to overestimating (the Nannoolal et al., 2008, method was found to have a relatively low overall bias in O'Meara et al., 2014).

Figure 7b demonstrates a useful plotting tool (script name: vol_contr_analys) available to PyCHAM users for analysing the contribution of components in a volatility basis set (i.e. grouped into different volatility bands) to secondary particulate matter. This plot relates to the no-wall simulation in Fig. 7a and indicates substantial changes to the mass fraction contributed by each volatility bin with time. Prior to dawn at approximately 4 h, relatively low-volatility components contribute significantly to SPM. Also using the PyCHAM script vol_contr_analys, a comma-separated value file with the vapour pressures and mass concentrations of individual components in the particle phase is produced. Analysis of this file shows that for the volatility band centred on µg m−3, the component with MCM called C536OOH dominates the mass fraction, though we note that when checking the no-wall curve in Fig. 7a, its absolute contribution to SPM is negligible relative to later SPM values. C536OOH has three carboxylic acid groups and a ketone group. Whilst such highly functional components are expected to have relatively low vapour pressures, we advise readers of the high error associated with estimated vapour pressures for such components; Fig. 5 of O'Meara et al. (2014) demonstrates an underestimation by 6 orders of magnitude compared to measurements.

To guide constraint for wall loss parameters, we follow the example of Matsunaga and Ziemann (2010), with a control experiment comprising a single semi-volatile component introduced to the chamber at the start of the simulation at 50 ppb. 2-Methylglyceric acid is selected as it has an estimated particle mass concentration saturation vapour pressure (C*) of 1.15×102 µg m−3 at 298.15 K (the simulation temperature) and is an observed oxidation product of isoprene (Surratt et al., 2006). No other components or particles are introduced. With regards to designing a control experiment for tuning Cw and kw, the results shown in Fig. 7c demonstrate that a component with a C* close to the Cw value has large sensitivity to Cw, thereby allowing the greatest ease of tuning. Note that this sensitivity can be utilised by varying chamber temperature (and therefore the C* of a component) or by using a component with different volatility. Furthermore, to discern the effect of kw a component with substantial partitioning to walls is required. When quantifying kw it is worth considering the required precision because above a certain value, no further effect on SPM concentration results.

Equations of coagulation kernels for Brownian diffusion, convective Brownian diffusion enhancement, gravitational collection, turbulent inertial motion, turbulent shear and Van der Waals collision were taken from Jacobson (2005). The unit test test_coag produces a plot of coagulation kernels that can be compared to Fig. 15.7 of Jacobson (2005) to verify accuracy. The number concentrations of newly coagulated particles are allocated to size bin k if they fit within the bounding volumes and do not include a particle originally from k; for combinations of size bins j and z the fraction of a newly coagulated particle contributing to size bin k is

where V is single particle volume, Vbk,l and Vbk,u are lower and upper volume bounds, respectively, and h is the time interval for coagulation to occur over. Particle number concentration in size bin k decreases when coagulation of k particles with those from any size bin produces a particle of size greater than the upper size bin bound of k. If, however, coagulation produces a particle within size bin k, there is no loss of number concentration if coagulation is with a smaller size bin. If the self-coagulation of k produces a particle in size bin k (a scenario dependent on the size bin width) the change is half that if the coagulated particle fits a size bin larger than k:

The semi-implicit coagulation equation from Jacobson (2005) is then used to estimate the new number concentration per size bin (N; ):

where A is the total number of size bins. It is necessary to solve Eq. (11) in ascending order of size bins because for the smallest bin, which cannot gain particles through coagulation, the term involving Nz,t is zero. This makes Eq. (11) explicit for the first size bin and allows estimates of Nz,t for larger size bins.

The semi-implicit approach has the advantage of being positive–definite and non-iterative, making it unconditionally stable and with lower processing time than an implicit numerical approach. However, whilst conserving number, Eq. (11) is not mass-conserving, whereas the implicit treatment (Jacobson, 2005) conserves both number and mass. It is the intention of the core development team to explore the feasibility of modelling with the implicit approach since guaranteed mass conservation is preferable. To estimate mass gained by size bin k due to coagulation, the number fraction of the original number of particles per size bin represented by coagulating particles is found, with this fraction of the original mass per size bin moved to the new size bin. Considering now gain in mass concentration rather than number concentration, the contribution from size bins smaller than k that coagulate with k must be considered, so

Now, for size bin k, the gain in mass concentration (C) of component i from smaller size bins (z) (based on Eqs. 11 and 12) is

For the loss of mass concentration from size bin k, size bin pair fractions become

Loss of mass concentration due to coagulation of particles in k, producing particles in larger size bins, is then (based on Eqs. 11 and 14)

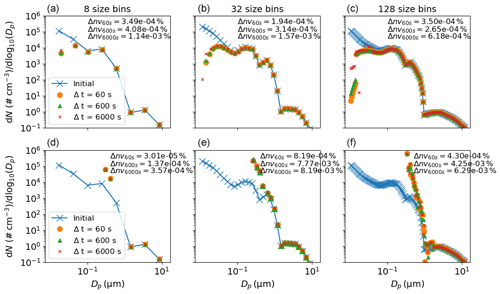

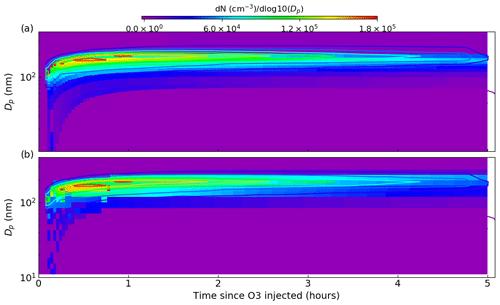

Equations (10)–(15) imply that coagulation directly influences the particle number and mass size distributions. We now assess the sensitivity of the number size distribution and mass conservation to the temporal resolution (represented by the time interval for updating coagulation) and number of size bins. A relatively complex initial distribution with four number modes is taken from ambient observations at Claremont, California, on 27 August 1987 (Jacobson, 2005) and assumed to comprise non-volatile material. Results are presented for a 6 h simulation in Fig. 8 where particle wall loss was turned off to allow clearer assessment of the coagulation sensitivity. In the top row of Fig. 8 no gas-phase chemistry was allowed, whilst in the bottom row, a single chemical reaction with a reaction rate of between α-pinene and O3 (both with initial concentrations of 100 ppb) was modelled to produce a single low-volatility product with a saturation vapour pressure of Pa, whilst gas–wall partitioning was turned off. For the chemistry case, approximately 500 µg m−3 of secondary material was formed compared to 90 µg m−3 of seed material. Columns in Fig. 8 are distinguished by the number of size bins as presented in the column titles, and within each plot temporal resolution is varied.

Figure 8Sensitivity of the coagulation process to changes in the temporal resolution (given in the legend) and number of size bins (given in column titles). In the top row no chemistry occurred, whilst in the bottom row a semi-volatile species was produced, as detailed in the main text. Results are for the end of a simulated 6 h experiment. The Δnvtemporal resolution value given in the inset text is the percentage change in total non-volatile particle-phase material from the start to the end of the experiment, demonstrating mass conservation in the model.

The inset text in Fig. 8 (Δnv) gives the fractional change in non-volatile material from the start to end (6 h) of the simulation for the three temporal resolutions. It is clear that the coagulation equations introduce negligible error to mass conservation. Two features are present in the top row (no chemistry) of Fig. 8: first, in terms of number concentration, coagulation overwhelmingly affects the number concentration of smaller particles – note that such particles are sufficiently small in volume that they may coagulate with a larger particle without causing it to grow a size bin. Second, only for the smallest particles (below a diameter of µm in this case) is a sensitivity to temporal resolution clear across all size bin resolutions. For the no-chemistry case there is demonstrable coupling of the number of size bins and temporal resolution, with an increase in the former indicating greater sensitivity to the latter. However, the resolution considerations change substantially when we consider the case with gas–particle partitioning in the bottom row of Fig. 8. In this instance, the effect of partitioning dominates the change in number size distribution and no sensitivity of coagulation to the number of size bins or temporal resolution is discernible. This is consistent with the typical timescales associated with the two processes: seconds to minutes for gas–particle partitioning and minutes to hours for coagulation (Seinfeld and Pandis, 2006). We recommend that users consider these examples in addition to the nature of their simulation and objective when deciding whether temporal resolution or the number of size bins will significantly impact results.

As with gas–wall partitioning, the loss of particles to chamber walls can significantly invalidate chamber results if unaccounted for, and this has been detailed in previous publications (Crump and Seinfeld, 1981; McMurry and Rader, 1985; Nah et al., 2017; Wang et al., 2018). During control experiments the deposition rate of particles to walls can be inferred through observations of the rate of decay of particles of varying size (with coagulation accounted for) (Charan et al., 2019). Several studies have published results from such experiments (McMurry and Rader, 1985; Wang et al., 2018), including a relatively large dataset from the EUROCHAMP2020 project (Oliveri, 2018). Comparison of inferred wall loss rates indicates that diffusion and settling enhance the loss rates of relatively small and relatively large particles, respectively (Crump and Seinfeld, 1981); however, the absolute values and size-dependent gradient of the loss rates vary significantly between control experiments. Even for a given chamber, significant variations appear with changes to relative humidity, disturbance to walls due to air conditioning and, for Teflon chambers, time since the chamber walls experienced frictional force to create electrostatic charge (Wang et al., 2018). Currently, no method is available to measure the required inputs that a particle deposition model would need to satisfactorily reproduce observations across all chambers and conditions; therefore, in PyCHAM users have three options to estimate particle wall deposition. Here we describe the options and provide examples of their use.

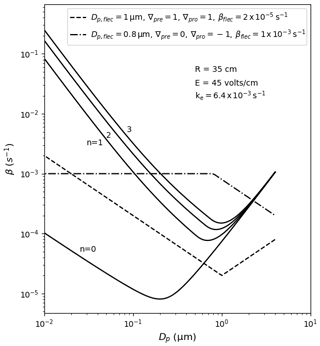

Users select wall loss treatment with the McMurry_flag option in the input file containing model variables. The default (if left empty) is no loss of particles to walls, which can be used to estimate wall-loss-corrected values such as aerosol yield. If set to 1, the model of McMurry and Rader (1985) is used, which is based on the particle deposition model of Crump and Seinfeld (1981) but with electrostatic effects. Studies have found the Crump and Seinfeld (1981) and McMurry and Rader (1985) approach to reproduce measured particle wall losses well (Chen et al., 1992; Kim et al., 2001). Selecting McMurry and Rader (1985) requires the user to also input the chamber surface area, the average charge per particle and the average electric field inside the chamber; the latter two may be set to zero to nullify electrostatic effects. With the test_wallloss module users can confirm that PyCHAM accurately reproduces Fig. 2 of McMurry and Rader (1985), as shown here in Fig. 9, which demonstrates the effect of changing the charge number per particle.

Figure 9Example dependencies of the rate of particle deposition to walls using the model of McMurry and Rader (1985), shown by the solid lines; the charge per particle is given by n, and other inputs are given in the inset text (R is spherical-equivalent chamber radius, E is the average electric field in the chamber and ke is the coefficient of eddy diffusion). The dashed lines demonstrate the observation-based deposition rate utility of PyCHAM given in Eq. (16), with inputs at the top of the plot.

If user sets the McMurry_flag option to zero then a customised particle deposition rate dependence on particle size is available. This option allows the application of known or best-estimate deposition rates (β) to the model, as recommended by Wang et al. (2018). Three further inputs are required for this option: the particle diameter (m) at which the inflection in deposition rates occurs (Dp,flec) (the inflection point marks a change in the dependance of deposition rate with particle size), the rate of particle deposition to walls (s−1) at the inflection point (βflec), and the gradients (s−1) of the deposition rate with respect to particle diameter before (∇pre) and after the inflection (∇pro), whereby a linear dependence in log–log space is assumed, consistent with observations (Charan et al., 2019). The equations for deposition rate in this instance are given in Eq. (16), and example dependencies of the rate with particle size are provided by Fig. 9.

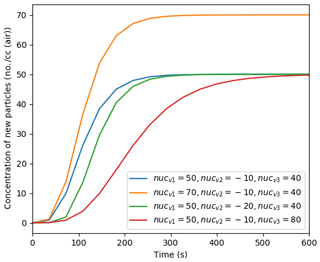

The simulation of nucleation to produce newly formed suspended particles is one of the most active areas of ongoing atmospheric research, and many important advances in observing the nucleation process have been, and will continue to be, made through appropriate measurements in chamber experiments and their interpretation (Dada et al., 2020). PyCHAM is not intended to interpret and examine chamber experiments designed to resolve the mechanisms involved in molecular clustering, nucleation and early growth in particle formation, and there are tools much better suited to these processes. However, the use of PyCHAM in simulating chamber processes in the presence of new particle formation necessitates a phenomenological accommodation of the process. Users are therefore able to provide parameters to a Gompertz function for cumulative new particle number, allowing them to fit to observed number size distributions without inferring mechanistic insight:

where P1 () is the number concentration of new particles after time t that enter the smallest size bin, and nucvn represents the user-defined parameters. As demonstrated in Fig. 10, the resulting function forms an asymmetric sigmoidal curve with time, whilst the parameters allow the amplitude (nucv1), onset (nucv2) and duration (nucv3) of the curve to be adjusted. Figure 10 is a general example not related to a specific chemical system as Eq. (18) is independent of chemistry. It is left to the user to vary the nucleation parameters to fit their observations. As Fig. 10 shows, the Gompertz function provides a sigmoidal form beginning with a relatively fast increase in new particle formation before the formation rate peaks, followed by a relatively slow levelling-off. This characteristic is consistent with observations of new particle formation, including Fig. 2b of Riccobono et al. (2014), and other simulations of nucleation, such as Fig. 2b of Dada et al. (2020).

For the moving-centre size structure in PyCHAM, newly nucleated particles determined by Eq. (18) enter the smallest size bin. In contrast, for full-moving, the approach of Roldin et al. (2015) is used whereby the new smallest size bin is formed on every step involving nucleation whilst removing the largest size bin (merging any particles and components present in this bin with those in the second-largest size bin).

As with gas–wall partitioning parameters, nucleation parameters should be fitted to measurements by minimising model–observation residuals. For this process the total particle number concentration may be used; however, the greater amount of data in number size distributions introduces stronger constraints, making it the preferred observation for fitting. In Fig. 11 we demonstrate PyCHAM simulations fitted to observations of a nucleation event from the Manchester aerosol chamber, which had initial concentrations of NO2 (40 ppb), O3 (60 ppb) and limonene (215 ppb). The experiment was dark at a constant temperature of 298.15 K and relative humidity 50 %. For Eq. (16), parameters were set to m, s−1, ∇pre=1 s−1 and ∇pro=1 s−1, which gave reasonable agreement with observed particle number decay. Here the same chemical scheme as in Fig. 1 was used, namely the MCM limonene scheme with appended PRAM scheme.

Figure 10Effect of varying the nucleation parameters on simulated particle number concentration when considering only nucleation.

The smallest size bin for which observations were obtained had a central diameter of 44 nm. Consequently, fitting was performed against measurements for particle sizes greater than those of newly formed particles. The implication for the derived nucleation parameters of Eq. (18) is that if any inaccuracy in non-nucleation processes (gas–particle partitioning, coagulation, particle loss to walls, gas–wall partitioning, gas-phase reaction affecting condensable vapour concentration) is present, these parameters will try to compensate when fitting to observations by minimising observation–simulation residuals. Ideally, measurements would therefore be available for the concentration of only newly nucleated particles, which would allow the fitted nucleation parameters to be independent of any convoluting process.

To minimise any possible effects from coagulation and particle loss to walls on fitting nucleation parameters, only the first hour of the experiment is considered when estimating residuals. Where necessary, simulation output was linearly interpolated to observation time and particle size points. Observation–simulation residuals (σ) for the number size distribution (nsb) were estimated using

where Z is the number of time steps, Y is the number of size bins, ti is the time step index, k is the size bin index and nlr is the particle number concentration from the simulation, whilst is that from observations. The denominator is the sum of the total particle number concentration from both the simulation and observations. Where number size distributions are in complete disagreement (with results having number concentrations in entirely different size bins), this denominator limits deviation to a helpful (for interpretation) maximum of 100 %. Exact agreement is represented by a σnsb of 0 %.

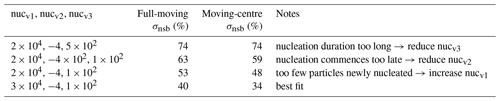

For a range of Eq. (18) nucleation parameters, Table 1 presents the observation–simulation residuals according to Eq. (19). The temporal profiles of the number size distributions for the entire experiment are shown in Fig. 11, with the model result here from the simulation with a minimal residual. In Fig. 11 simulation results are represented by the filled contours, whilst observations are given by the contour lines.

Table 1Observation–model residuals as defined by Eq. (19) for a dark limonene oxidation experiment without seed particles; the experiment setup is described in the main text. Residuals are given for a variety of nucleation parameters, with the minimum residual representing the best fit of the simulation to observations.

Figure 11Comparing number size distributions from best-fit (defined in Table 1) PyCHAM simulations using the full-moving (a) and moving-centre (b) size structures against observations from a dark limonene oxidation chamber experiment with nucleation. Experiment conditions and simulation setup are given in the main text. Observations are presented as contour lines, whilst model results are filled contours, with both using the colour axis given at the top of the plot. The degree of agreement here is indicated by the difference in these contours at any one point.

With the shape, size, composition and growth mechanism of the clusters that act as the nucleus of particles subject to ongoing research, in PyCHAM default properties are currently assigned, with a view to advancing representation as understanding develops with an appreciation of their physical limitation. An arbitrary involatile component is assumed to form spherical nucleating clusters with a radius of 2 nm. Growth of clusters is assumed to follow gas–particle partitioning (as for particulates of all sizes in PyCHAM). At the current stage of development, this representation of new particle formation in PyCHAM aims to enable simulations of coupled photochemistry and aerosol microphysics in seeded and unseeded experiments. However, a more rigorous mechanistic representation of nucleation and early growth should be readily accommodated and will be required before PyCHAM is suitable for investigating new particle formation.

In PyCHAM, temporal resolution is set by the user, as represented by the time interval for updating ODE constants, and the size bin number is also set by the user (Sect. 3). Whilst decreasing both resolutions can decrease processing time, inaccuracies may be introduced because PyCHAM processes are sensitive to changes to number size distributions (updated after each time interval) and particle size. Although it is beyond the scope of this paper to assess resolution sensitivity across all possible PyCHAM parameter space, in this section we compare the divergence of outputs from simulations with decreasing temporal resolution and size bin number against a high-resolution reference for extremes of the relevant parameter space: seeded experiments with no gas–particle partitioning and both seeded and nucleation experiments with relatively large condensational growth of particles. As in Sect. 7, 2-methylglyceric acid is used in the simulations with partitioning as its vapour pressure at simulation temperature (298 K) makes it semi-volatile. Results here determine the recommended temporal resolution and size bin number, provide a useful illustration of sensitivity, and may help users perform sensitivity tests for their individual model inputs.

For the simulations without partitioning, the effect of resolution on particle number size distribution and total number concentration is considered, whilst for the partitioning simulations, the concentration of secondary material is also relevant. To allow comparison of low-resolution simulations with the high-resolution reference, linear interpolation is used to estimate output from the former at the resolution of the latter. Divergence between a low-resolution simulation (lr) and the high-resolution reference is represented by a single absolute percentage deviation (σ). For number size distribution, deviation (σnsb) is found by Eq. (19), with representing the high-resolution result.

For total number concentration and total secondary particulate matter concentration, deviation (σlr) is calculated as the percentage deviation:

where Z is the total number of time steps, and H represents either total number concentration or total secondary particulate matter concentration. The use of (the maximum of either the low-resolution or high-resolution result for a given time step is used for the summation) for the denominator means that when one result is zero and the other is above zero (maximum possible disagreement) a helpful (for interpretation) σlr of 100 % is produced, whilst complete agreement gives a σlr of 0 %.

For simulations assessing sensitivity to temporal resolution, 128 logarithmically spaced size bins are used, for which Fig. 8 indicates no limitation to accuracy due to size bin number. For seeded simulations, we use the same initial number size distribution as in Fig. 8, as this gives a relatively broad range of particle sizes, which is necessary to fully appreciate the size-dependent effects of coagulation, particle loss to walls and nucleation. All simulations were run for 24 h, and the reference simulation had an update time interval of 6 s.

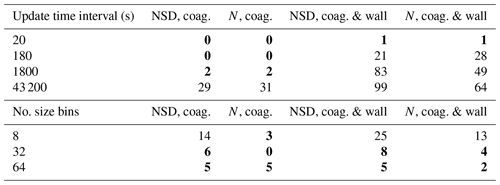

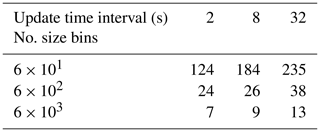

Results for each scenario (seeded with no partitioning; seeded with partitioning; nucleation with partitioning) are provided in Tables 2–4. The first, given in Table 2, represents the no-partitioning case, with sensitivity assessed for two setups: only coagulation and both coagulation and wall loss turned on. Coagulation proceeds as described in Sect. 8, whilst wall loss is described in Sect. 9, with the following inputs to recreate a size-dependent wall loss profile similar to n=3 in Fig. 9: .0 µm, s−1 and . Consequently, the particle loss to walls is relatively large and the sensitivity results are conservative. Table 2 indicates that under this scenario, particle loss to walls considerably increases sensitivity to temporal resolution compared to the only coagulation case, with much finer resolutions required to achieve average deviations of 10 % or less.

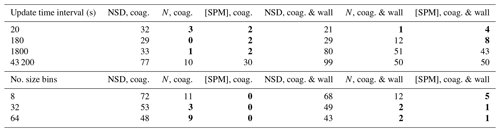

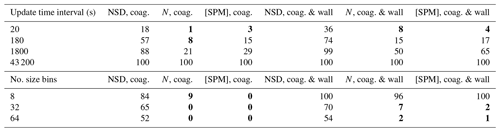

For Table 3, 2-methylglyceric acid is introduced at a rate of ppb s−1. Comparing the NSD (number size distribution) columns in Tables 2 and 3, including gas–particle partitioning acts to increase sensitivity to temporal resolution. However, there is less change overall for sensitivity of N and [SPM]. A resolution of around 180 s is required to attain deviations around 10 % or less for total number concentration and secondary material, whilst for number size distribution, not even the lowest temporal resolution of 20 s can agree within 10 % with the reference case of 6 s. This reflects the steep gradients of particle number with particle size that are generated during intense condensational growth periods (e.g. Fig. 6). This effect is also evident when an extremely low-volatility organic component is injected at the simulation start at 1 ppb to act as a nucleating agent in an unseeded simulation, with results given in Table 4. We use the nucleation parameters for Eq. (18) of , and for a relatively rapid nucleation period (lasting only 10 min) and therefore conservative assessment of sensitivity. Table 4 shows that the total number and secondary material concentrations deviate from the reference case by around 10 % for an update time interval of between 20 and 180 s. Given the conservative nature of these simulations we therefore recommend a maximum update time interval of 60 s. However, with the coagulation case effectively representing zero wall loss and showing considerably less deviation across all scenarios, if users can demonstrate relatively low particle wall loss, a coarser resolution could be applied.

Table 2Percent deviation from the high-resolution reference case for the seed without partitioning (non-volatile particles in the absence of vapours) scenario for number size distribution (NSD) (Eq. 19) and total particle number concentration (N) (Eq. 20). The top section of the table shows sensitivity to temporal resolution (update time interval) using 128 size bins, whilst the bottom section shows sensitivity to size bin number (number of size bins) using a 60 s update time interval. Columns headed “coag.” are for simulations wherein coagulation acts alone, whilst columns headed “coag. and wall” are for simulations with both coagulation and particle loss to walls.

Values in bold – less than 10 %.

Table 3Percent deviation from the high-resolution reference case for the seed with partitioning scenario. Condensation occurs due to the continuous injection of 2-methylglyceric acid vapour at a rate of ppb s−1. In addition to the particle properties described in Table 2, the concentration of secondary particulate matter ([SPM]) is also evaluated here using Eq. (20).

Values in bold – less than 10 %.